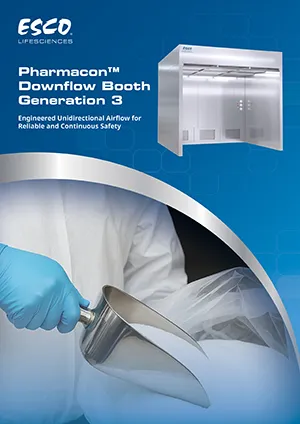

Pharmacon™ Downflow Booth Generation 3 (DFBG3)

Esco Pharma's Downflow Booth Generation 3 (DFBG3) is a new generation of Esco powder containment booth which provides simplicity with assured quality. Downflow booth is used for non-aseptic, opening sytem ambience booth. The Esco Downflow Booth ensures operator and process protection using HEPA-filtered laminar downflow air to prevent the powders deposit to the operator breathing zone via the negative pressure principle during open handling processes such as weighing, dispensing and sampling. With various configurations provided, DFBG3 adapts to your specific needs with fully customizable options. Its flexible design suits a wide range of applications across various industries.

Pharmacon™ DFBG3 Applications

- Pharmaceutical

- Cosmetic

- Nutraceutical

- Food

- Electronic

NEW FEATURES!

Standard Safe Change Filter version

The backstack is specifically designed for the Safe Change Filter of the Air Return filter(s). This will suit your potent/hazardous powder handling.

Enhanced flush mounted design

This is equipped with lighting and local operating panel flush mounted design to provide a smooth surface of ceiling.

Hassle-free and quick maintenance access for the Pre-Filter replacement

The pre-filter housing cover is designed with the hinges, by swinging down the panel without hassle to remove out the cover panel from the mounting which costs more time to manage during the filter replacement.

Other Features

Filter configuration options to protect the environment and operator.

Filtration stage order:

- G4-Pre-filter

- F8-Fine Dust – Stage 1

- H13-HEPA filter - Stage 2

- H14-HEPA filter downflow air - Stage 3

Local operating panel with Smart controller

Its new system allows for simple operating yet assured monitoring. Customization of HMI/PLC Allen-Bradley/Siemens is available.

•

Downflow air is delivered into the Operator’s Breathing Zone (OBZ) via

the overhead HEPA filters, thus providing a safe environment for the operator

to work.

•

Potential dust clouds are suppressed and removed via the exhaust

filtration system via the optimized filtration.

• The operator carries out tasks in the high velocity zone at the rear of the Booth so that dangerous dust will not rise into the breathing zone.

| Guide to DFBG3 Model Code | |||||||

| Model | DFBG3-SC-16-20-25-F-PB-CC | ||||||

| Product Code | Filter replacement | Internal dimensions | Bleed position | Controller Type | Cooling coil | ||

| width | depth | height | |||||

| DFBG3 | SC - Safe Change | 16 - 1.6 m | 20 - 2.0 m | 25 - 2.5 m | F - Front | PB - Push Button with Smart Controller - Pressure Gauge - Open Loop – PB/PDI/Open Loop | NIL - Not required |

| * | * | * | T - Top | AB - 7" HMI/PLC Allen Bradley - Closed Loop – HMI Allen-Bradley/PLC/Closed Loop | CC - Chilled water | ||

| SM - 7" HMI/PLC Siemens - Closed Loop Closed Loop – HMI Siemens/PLC/Closed Loop | DX - Direct Expansion | ||||||

| GL - Glycol | |||||||

DFBG3 SAFE CHANGE FILTER MODEL CONFIGURATIONS

| No. | Internal Width (mm) | External Width (mm) | Internal Depth (mm) | Safe Working Zone | Back Stack Depth (mm) | Internal Height (mm) | External Height (mm) |

|---|---|---|---|---|---|---|---|

| 1 | 1600 | 1800 | 2000 | -400 mm from the Internal Depth | 1090 | 2500 | 3000 |

| 2 | 2500 | ||||||

| 3 | 3000 | ||||||

| 4 | 1800 | 2000 | 2000 | ||||

| 5 | 2500 | ||||||

| 6 | 3000 | ||||||

| 7 | 2000 | 2200 | 2000 | ||||

| 8 | 2500 | ||||||

| 9 | 3000 | ||||||

| 10 | 2200 | 2400 | 2000 | ||||

| 11 | 2500 | ||||||

| 12 | 3000 | ||||||

| 13 | 2400 | 2600 | 2000 | ||||

| 14 | 2500 | ||||||

| 15 | 3000 | ||||||

| 16 | 2600 | 2800 | 2000 | ||||

| 17 | 2500 | ||||||

| 18 | 3000 | ||||||

| 19 | 2800 | 3000 | 2000 | ||||

| 20 | 2500 | ||||||

| 21 | 3000 | ||||||

| 22 | 3000 | 3200 | 2000 | ||||

| 23 | 2500 | ||||||

| 24 | 3000 | ||||||

| 25 | 3200 | 3400 | 2000 | ||||

| 26 | 2500 | ||||||

| 27 | 3000 | ||||||

| 28 | 3400 | 3600 | 2000 | ||||

| 29 | 2500 | ||||||

| 30 | 3000 | ||||||

| 31 | 3600 | 3800 | 2000 | ||||

| 32 | 2500 | ||||||

| 33 | 3000 | ||||||

| 34 | 3800 | 4000 | 2000 | ||||

| 35 | 2500 | ||||||

| 36 | 3000 | ||||||

| 37 | 4000 | 4200 | 2000 | ||||

| 38 | 2500 | ||||||

| 39 | 3000 | ||||||

| 40 | 4200 | 4400 | 2000 | ||||

| 41 | 2500 | ||||||

| 42 | 3000 | ||||||

| 43 | 4400 | 4600 | 2000 | ||||

| 44 | 2500 | ||||||

| 45 | 3000 | ||||||

| 46 | 4600 | 4800 | 2000 | ||||

| 47 | 2500 | ||||||

| 48 | 3000 |

| General Specifications | ||

| Safe Change Filter Design | ||

| Back stack | 1090 mm (43") | |

| Booth type | Safe Change No Bag | |

| Safe Change With Bag | ||

| Area rating | Safe Area Optional for Explosive Rating booth |

|

| Dimensional Options | Internal Width (m) | 1.6, 1.8, 2.0, 2.4, 2.6, 2.8, 3.0, 3.2, 3.4, 3.6, 3.8, 4.0, 4.2, 4.4, 4.6, 4.8 (External width is +200 mm from the Internal Width) |

| Internal Depth (m) | 2.0, 2.5, 3.0 | |

| Internal Height (m) | 2.5 (External height is +500 mm from the internal height) | |

| Filter arrangement Options | G4, F8, H13, H14 Option to Carbon Filter |

|

| Fan/Filter Access | External Area | |

| Internal Area | ||

| Airflow Arrangement | Standard: Recirculating with bleed out air | |

| Option: Single Pass with Downflow | ||

| Safe working zone | Internal depth - 400 mm | |

| LOP Location | Rear wall | |

| Option: Side panel - Right/Left | ||

| Bleed position | Front | |

| Material of Construction | Ceiling plenum | SS316 SS304 White EG Steel Powder Coated |

| Side panels, Rear wall | ||

| Filter housing, fan box, Space (if any) & transition | ||

| Plinth | ||

| Exhaust grills | ||

| Exterior side panels | ||

| PVC curtain | NIL | |

| Option: add-on | ||

| Voltage supply | 400 V, 50 Hz, 3 Ph | |

| 480 V, 50 Hz, 3 Ph (United State of America) | ||

| MCP Location | Remote mounted | |

| On-board | ||

| Control Type | Push Button with Smart Controller - Pressure Gauge - Open Loop | |

| Option to HMI/PLC Siemens/Allen Bradley - Open Loop/Closed Loop | ||

| Cooling Type | Chilled water/Glycol | |

| Direct Expansion | ||

| PAO Ports | Inner ceiling | |

| OPTIONS | |||

| Mobile High Containment Screen | Penetration cut-out only for Side Wall or Ceiling Fire Sprinkler | ||

| Benches; SS or Granite Tables, Fixed to Booth or Stand Alone | Vision/Window Panel | ||

| Material Handling, Roller Conveyor for Drum Handling | Temperature & RH Local Display | ||

| Airlock Room | Ethernet & RS-232 Pass-through connection | ||

| Electrical Outlets, Splashproof or IP rated or Explosive Rated | Bumper Rails | ||

| Pass-through Box | HMI Controller | ||