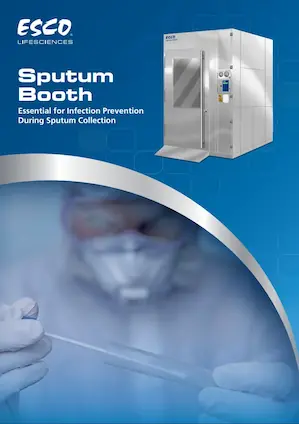

Esco Sputum Booth (ESB)

Esco Sputum Booth (ESB) is designed for use in hospitals, labs, and medical research facilities. It controls exposure risk to harmful aerosols/airborne diseases by providing containment through air flow to capture and exhaust aerosols from sputum during expectoration, handling, or processing. We provide both operator and patient safety, as well as environmental protection.

ISO Class 7 air cleanliness as per ISO 14644-1

-

Negative pressure keeps aerosol contained in booth:

Supplies 100% HEPA filtered / fresh air to the downflow plenum

Typical airflow is 85% total volume as downflow, 15% inflow and 100% exhausted

UV lamp operates on programmable timer embedded in the Sentinel™ Microprocessor System

Emergency stop, intercom for easy communication between operator and patient, LED lamp, On/Off switch included

-

Material of construction:

SS304 grade

SS316L grade

Electrogalvanized steel coated with ISOCIDE™

Reinforced SS304 or SS316L finish sheet metal floor

SS316L or electrogalvanized steel coated with ISOCIDE™ door with tempered glass transparent windows

Detachable wall-mounted stainless steel perforated workbench

Adjustable and movable stainless-steel chair

Concealed leveling feet

Wheelchair accessible chamber

Room air is taken from the top of the booth through a disposable pre-filter; air is forced evenly across the HEPA filter, resulting in a clean downward airflow.

Purified air travels downward within the interior in a vertical, downward stream with a velocity of 0.16 ± 20% m/s and leaves the 2-stage exhaust filter into the room close to the left-front side wall.

Supply and exhaust fan / filter systems will be individually designed for each location.

|

Guide to Models |

|||||||||

|

SB – S 115 150 193 – 1 – C |

|||||||||

|

Product Code |

- |

Material of Construction |

Internal Dimensions |

- |

Electrical Requirement |

- |

Customization |

||

|

Width (cm) |

Depth (cm) |

Height (cm) |

|||||||

|

Sputum Booth |

|

S – Stainless Steel 304 |

115 |

150 |

193 |

|

1 – 220-240V, 50Hz, 1Ph |

|

C – Customization No Customization |

|

|

B – Stainless Steel 316L |

* |

* |

* |

|

2 – 110-120V, 50Hz, 1Ph |

|

||

|

|

A – EG Steel with ISOCIDE™ powder coating |

|

|

|

|

3 – 220-240V, 60Hz, 1Ph

|

|

||

|

GENERAL SPECIFICATION |

||

|

Model |

SB-S115150193-1-C |

|

|

Internal Dimension (W x D x H) |

1600 x 2000 x 2300 mm |

|

|

External Dimension (W x D x H) |

1150 x 1500 x 1930 mm |

|

|

Filter |

G4 Pre-Filter, H13 Downflow HEPA Filter, H13 Return Grill HEPA Filter,

H14 Exhaust HEPA Filter |

|

|

Cabinet Construction |

Main Body |

Stainless Steel Grade 304/ SS316L / Electrogalvanized steel coated

with ISOCIDE™ powder coating Sheetmetal |

|

Floor |

Stainless Steel Grade 304 / SS316L |

|

|

Door |

Stainless Steel Grade 316L / Electrogalvanized steel coated with

ISOCIDE™ powder coating Sheetmetal |

|

|

CMH |

350 m3/hr (100% Exhausted) |

|

|

Est. Power Consumption |

350 W, 10A (Full Load Amps) |

|

|

Min. Light Intensity |

≥ 500 Lux |

|

|

Min. UV Intensity |

≥ 40 µW/cm2 |

|

|

Noise Level |

≤75 dB |

|

|

Est. Gross Shipping Weight |

SB with MOC of

SS304 Standard Dimension |

|

|

Pallet 1: 499 kg |

||

|

Pallet 2: 753 kg |

||

|

SB with MOC of EG

Steel Standard Dimension |

||

|

Pallet 1: 430 kg |

||

|

Pallet 2: 555 kg |

||

|

Est. Shipping Dimension |

SB with MOC of

SS304 and EG Steel Standard Dimension |

|

| Pallet 1: 2050 x 850 x 1540 mm |

||

|

Pallet 2: 2400 x 1150 x 1860 mm |

||

|

Inclusive |

With 2 electrical outlets |

|

|

3 x BMS relay signal for airflow, downflow DP

filter, exhaust DP filter |

||

Pre-Filter: A disposable G4 pre-filter with 90% efficiency

Downflow Filter (Main Supply Filter): HEPA (H13) filter

Exhaust 1st Stage: HEPA (H13) filter

Exhaust 2nd Stage: HEPA (H14) filter on Esco Fan Filter Unit provides 99.995% at 0.3 microns at MPPS (Most Penetrating Particle Size)

LED lamp

UV lamp

.webp)