Cleanroom Air Showers (EAS)

Esco Air Showers (EAS) are self-contained chambers strategically positioned at cleanroom entrances and other controlled environments. These chambers minimize particulate matter from infiltrating the clean space. As personnel pass through, the EAS “scrubs” by high velocity HEPA-filtered air jets at 18-30 m/s (3,543 - 5,906 fpm). The contaminated air is drawn from the base, filtered, and then recirculated into the chamber maintaining a clean environment.

Esco is the pioneering company for the manufacture and construction of cleanroom air showers with

different applications in the following areas:

- micro-electronics

- semiconductors

- pharmaceutical

- spray painting

- laboratory animal research

- food markets

With greater than 40 years of experience in the industry, Esco is consistently manufacturing, and supplying reliable air showers and clean air solutions to reduce the potential for cross-contamination, and enhance cleanroom integrity.

High-velocity air jets

High velocity shower jets in excess of 20 m/s to ensure efficient scrubbing action to remove particulate matter.

Stainless steel nozzles

Permanently lubricated direct drive centrifugal blowers used in conjunction with stainless steel 304 adjustable air nozzles.

Programmable operation

Operating modes can be programmed in the field.

Reliable microprocessor control system

Microprocessor controller supervises all functions.

High performance blower system

German-made ebm-papst® motor/blowers feature a compact, energy-efficient design with quiet, vibration-free operation.

H14 filtration

The typical efficiency of H14 filter is 99.995% at 0.3 micron particles.

Pre-filtration

A disposable prefilter with 90% efficiency.

Emergency buttons

An emergency stop button is mounted on both sides of the shower.

Indicator lights to signal door status

Indicator lights mounted on both sides of the exterior of the air shower to regulate traffic flow, in and out of the cleanroom.

Durable doors

Heavy-duty, durable aluminum framed doors with double layer clear glass windows to permit visibility.

Powder-coated steel construction

The air shower is constructed of electrogalvanized steel sheets with an abrasion- and microbial-resistant oven-baked powder coated finish. (Optional: Stainless steel 304 construction)

Uniform lighting

Light diffusers ensure uniform lighting throughout the chamber.

Modular Design

Allows for flexible configuration and easy maintenance.

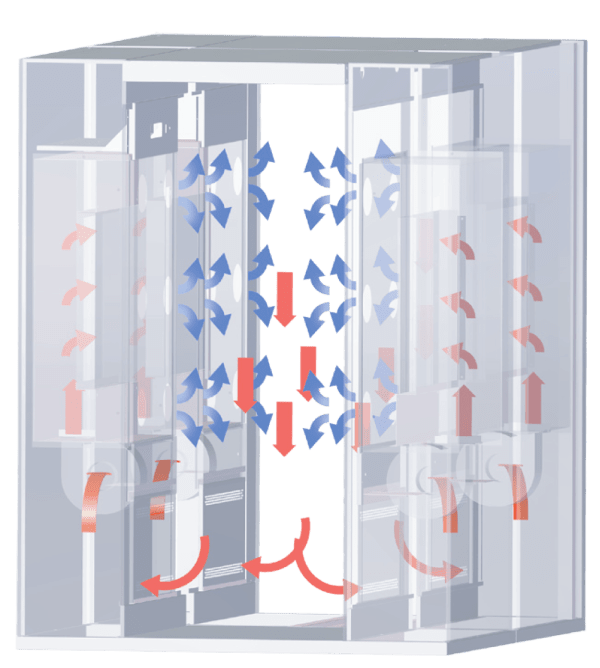

Air is forced by the blower(s) through H14 filter(s) which are 99.995% efficient against particles of 0.3 microns.

Filtered air is ejected through nozzles at high velocities into the chamber. These turbulent air streams disperse particulate matter on all surfaces.

Dispersed particulate matter migrates with the air stream towards the lower areas in the air shower chamber. Air enters the blower supply plenum through pre-filter(s) installed at the base of the chamber.

The air is continuously filtered and recirculated. The air shower is a self-contained device and does not exchange air with the environment it is placed in.

|

Criteria |

EAS Model Series |

|||||||

|

A Series |

B Series |

C Series |

||||||

|

1A |

2A |

3A |

1B |

2B |

3B |

2C |

3C |

|

|

No. Of Nozzles |

6 |

12 |

18 |

12 |

24 |

36 |

24 |

36 |

|

Persons per Cycle |

1 |

2-3 |

1 |

2-3 |

2-3 |

4-6 |

||

|

External Dimensions |

1260 x 1000 x 2055 mm (49.7" x 39.4" x 80.9") |

1260 x 2000 x 2055 mm (49.7" x 78.7" x 80.9") |

1260 x 3000 x 2055 mm (49.7" x 118.1" x 80.9") |

1530 x 1000 x 2055 mm (60.2" x 39.4" x 80.9") |

1530 x 2000 x 2055 mm (60.2" x 78.7" x 80.9") |

1530 x 3000 x 2055 mm (60.2" x 118.1" x 80.9") |

2330 x 2000 x 2055 mm (91.7” x 78.7” x 80.9”) |

2330 x 3000 x 2055 mm (91.7” x 118.1” x 80.9”) |

Unlike conventional air showers which are delivered with a fixed operating sequence, the Esco Cleanroom Air Shower’s operating sequence may be selected from three pre-programmed sequences:

One-Way

(Left Illustration): Personnel may enter the controlled environment but not exit through the air shower. At the idle state, the clean side door is locked while the grey side is unlocked. This mode of operation is useful for controlling traffic patterns in and out of the controlled environment.

Two-Way One-Way

(Middle Illustration): Personnel may enter or exit the controlled environment through the air shower. The air shower will be activated if personnel enter from grey room. The air shower program is able to detect if the person is entering or exiting the controlled environment via door sensors and a time-sequenced control.

Two-Way

(Right Illustration): Personnel may enter or exit the controlled environment through the air shower. In both directions the air shower is activated. This mode of operation is useful in pharmaceutical and lab animal research applications to prevent the egress of hazardous substances and allergens from the controlled environment.

ACCESSORIES

- Emergency stop buttons (inside the EAS)

- Gauge for differential across filter monitoring

- Vertical shutter door

What are the benefits of integrating cleanroom air showers in controlled environments/ facilities?

Installation of Esco cleanroom air showers enables seamless entry/exit of personnel in and out of the controlled environment. The “scrubbing” effect of the high-velocity air showers on particulate matters or surface contaminants allows mitigation of potential cross-contamination; thereby increasing cleanroom and process integrity.

What is the initial air velocity of Esco cleanroom air showers?

Initial air velocity of Esco Air Shower (EAS) is 18-30 m/s (3543-5906 fpm).

What is the diameter of the air shower nozzles provided for EAS?

Air nozzles of EAS are adjustable, constructed with stainless steel 304, and are 25mm (1") in diameter.

What is the difference between the brochures Cleanroom Air Showers (also known as EAS) and Cleanroom Air Showers (EAS-EUS)?

In response to the increase in demands for a wider range of size selections for Esco cleanroom air showers, expansion in standard dimensions available for fast track processing is offered in the new EAS-EUS brochure.

The only difference between EAS and EAS-EUS is that the standard sizes available for the latter have bigger and wider dimensions in comparison to those available in the EAS brochure. Additionally, the EAS unit is equipped with aluminum-framed door, while the EAS model is equipped with EG steel framed door.

Model

External Dimensions Comparison

A Series

B Series

C Series

1A

2A

3A

1B

2B

3B

2C

3C

EAS

49.7" x 39.4" x 80.9"

49.7" x 78.7" x 80.9"

49.7" x 118.1" x 80.9"

60.2" x 39.4" x 80.9"

60.2" x 78.7" x 80.9"

60.2" x 118.1" x 80.9"

91.7” x 78.7” x 80.9”

91.7” x 118.1” x 80.9”

EAS-EUS

54.5” x 40.9” x 86.8”

54.5” x 81.9” x 86.8”

54.5” x 122.8” x 86.8”

65.15” x 40.9” x 86.8”

65.15” x 81.9” x 86.8”

65.15” x 122.8” x 86.8”

95.87" × 81.2" × 86.8"

95.87" × 1128" × 86.8"

How does Esco cleanroom air shower series (EAS-A/ EAS-B/ EAS-C) vary from each other?

- Airflow (EAS-A vs. EAS-B and EAS-C)

EAS-A is equipped with only one blower and filtration module on one side of the unit (Single Sided). This allows air shower installation in areas with limited spaces, while still allowing optimal “scrubbing” of particulate matter/ surface contaminants from personnel or materials.

EAS-B and EAS-C, on the other hand, have blower and filtration modules to facilitate airflow on both sides of the unit (Double Sided). - Door Leaf (EAS-A and EAS-B vs. EAS-C)

Both EAS-A and EAS-B series are equipped with single-leaf door, while EAS- C is built with double-leaf doors. EAS C-Series can accommodate more persons per air shower cycle as compared to the EAS A and B series.

- Airflow (EAS-A vs. EAS-B and EAS-C)

What is the typical efficiency of filter/s used for Esco cleanroom air showers?

The typical efficiency of the EAS filter is 99.995% at 0.3 micron particles.

Can Esco cleanroom air showers measure the differential pressure across filter?

Standard models of EAS are not designed with a device to measure and display differential pressure across filter. Upon client request, Esco can customize cleanroom air showers to have add-on Pressure gauges to display differential pressure value across filters.

How are Esco cleanroom air showers shipped?

Depending on client request and dimensions of ordered air shower, EAS can be shipped in assembled, module or unassembled form. Please refer to the brochure for shipping dimension and shipping volume details.