Ventilated Balance Enclosure (VBE)

The Ventilated Balance Enclosure (VBE) is designed specifically for stability and accuracy while maintaining a high level of operator protection during handling of hazardous airborne powders. With our aerodynamic sash design and arm rest plus a sectionalized baffle, the powders will be well-contained inside the enclosure and discharged through a HEPA filter or directly to the lab exhaust.

Key Features:

- Negative pressure application provides a high level of operator protection from hazardous airborne particles.

- The Isocide™ powder coated EG steel material of construction has antimicrobial properties (Optional: a full stainless steel construction).

- Single BIBO H14 Filter and EC blower (Optional: Double BIBO HEPA filtration).

- The disposal port is equipped with O-ring to provide a sealed trash bag, as an additional powder containment solution.

- VBE is equipped with a filter, a portable filter and a blower module for better airflow control.

- Sentinel™ microprocessor controller with visual display and alarms for airflow monitoring.

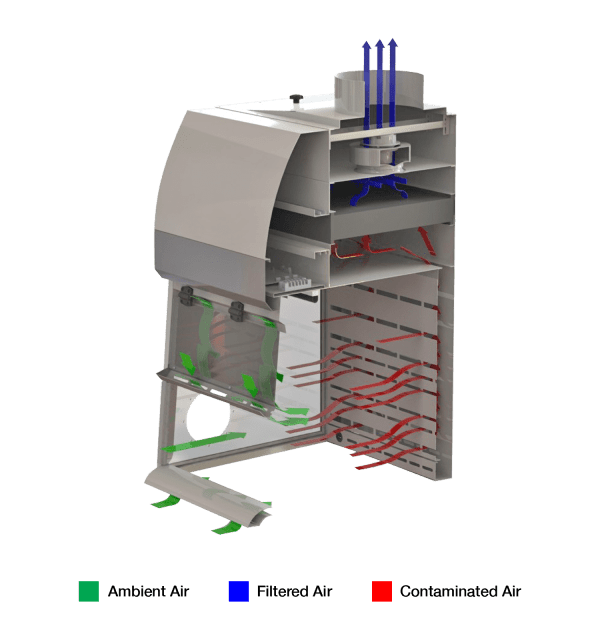

Optimized Airflow

This unit is equipped with an aerodynamic sash handle and arm rest to provide optimized airflow inside the enclosure.

- Air enters the VBE unit through the lower part of the work zone and the sash (via sash sweep to allow sweeping of airborne powders away from the sash).

- This air is then pulled by the blowers and passed through HEPA filters (Bag-In, Bag-Out) before being exhausted out of the unit.

Sentinel Microprocessor Controller

Provides control, visual monitoring, and alarm system.

Modular Design

The design of VBE is modular in terms of exhaust and filtration system allowing for flexibility and full customization.

Two Types of Filtration Systems

- Single Filtration: with only one HEPA (H14, >99.995% efficiency at 0.3 µm) filter in Bag-In, Bag-Out configuration.

- Double Filtration: with two HEPA (H14, >99.995% efficiency at 0.3 µm) filters in a series in Bag-In, Bag-Out configuration.

- Media: Glass Fiber

- Sealing Method: Gasket

- An additional carbon filter may be supplied for removal of volatile compounds or odor control.

Three Exhaust Options

- Ducted (Standard): recommended for handling volatile potent powders.

- Ductless: applicable for operations not associated with handling volatile materials.

- Portable Duct: recommended for facilities without a high ceiling clearance.

Wide array of VBE enclosure modules or configurations

Covers various operations involving powder weighing and dispensing.

- Standard (A): Perfect for small spaces, this solution helps end-users maximize ceiling space by incorporating portable filter options.

- Tall (B): Medium-sized models are ideal for handling tall equipment during powder weighing.

- Tall and Deep (C): Large models are ideal for large-scale powder handling and can be configured with a Worktop featuring a Drum Access option.

Constructed with Quality Materials

Electro-galvanized steel with white oven-baked epoxy polyester powder coating.

- The Isocide™ powder coating has antimicrobial properties.

- Options for a full stainless steel construction is also possible.

Ventilated Balance Enclosure is designed to safely and efficiently handle potent/toxic powders by continuously pulling air toward the cabinet’s work zone. This configuration ensures a negative pressured environment is always, thus preventing any unintended exposure to operators and the surrounding environment.

- Air enters the VBE unit through the open sash, via the lower/ middle part of the work zone and through the actual opening on the sash (via sash sweep to allow sweeping of airborne particles away from the sash).

- This air is then pulled through the back wall of the unit by the blowers and passed through HEPA filters (Bag-In, Bag-Out) before being exhausted out of the unit.

The unit is factory-tested as per the following:

- Airflow Velocity Check

- Confirms that the air velocity in the chamber is within the specifications and able to prevent cross-contamination in the facility.

- Filter PAO Leak Test

- To detect system leaks and ensure containment effectiveness for potent pharmaceutical powders.

- Noise Level Test

- Light Intensity Test

- Airflow Visualization Check

- Demonstrates the airflow pattern inside the VBE unit.

- Vibration Test*

|

Guide to Ventilated Balance Enclosure (VBE)

Models |

|||||||

|

VBE-2 A 8-03 S A |

|||||||

|

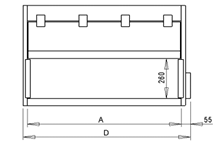

Model |

Internal Width (mm) |

Size |

Configuration |

Electrical Code |

Enclosure Module |

Filter Module |

Exhaust Type |

|

VBE |

610 |

2 |

A - Standard B - Tall C - Tall and Deep |

7 - 100V 50/60Hz |

01 - without filter and blower 02 - with filter 03 - with filter and blower |

S - Single Filtration D - Double Filtration |

A - Ducted B - Ductless C - Portable Duct |

|

915 |

3 |

8 - 230V 50/60Hz |

|||||

|

1220 |

4 |

9 - 115V 50/60Hz |

|||||

|

1525 |

5 |

|

|||||

|

1830 |

6 |

||||||

|

2135 |

7 |

||||||

|

2440 |

8 |

||||||

Optional Control System Package/s:

- Add-on RH/Temperature Sensor with LCD

Worktop option:

- Solid Epoxy (additional 91 mm in external height)

- Suitable for handling laboratory chemicals/reagents.

- SS 316 (additional 50 mm in external height)

- Granite (additional 91 mm in external height)

- Ideal for high accuracy weighing operations, as granite minimizes vibration.

VBE base options:

- Support stand

- Cabinet type base

- Support stand with drum access

In addition to this, Castor wheel or Leveling feet can be selected as footing options.

Additional Carbon filter:

- Carbon type: Organic, Acid, Mercury, Sulphur, Halogen, Aldehyde, Ammonia/Amine, Chloroform/Ethers.

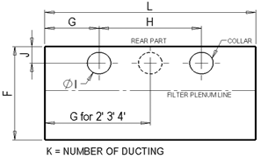

- Size:

- 2V (dimension: 420 mm x 457 mm x 65 mm; for VBE with 2 ft, 4 ft, 5 ft, and 8 ft internal widths)

- 3V (dimension: 420 mm x 762 mm x 65 mm; for VBE with 3 ft, 6 ft, and 7 ft internal widths)

Granite Slab:

- For VBE units without a granite top, this slab can be added to guarantee high accuracy of weighing readings. The client’s preferred weighing balance can be set up on top of this slab to remove traces of vibration.

- Please provide the dimensions (WxDxH) of the weighing balance upon ordering.

-

Are disposal ports standard by default?

Disposal ports are included as a default configuration with pre-installed covers.

-

Is the trash bag or disposal bag included for the disposal port?

The trash bag or disposal bag is not included for the disposal port as a standard.

-

What are the differences between Ventilated Balance Enclosure (VBE) vs Ascent Fumehood (ADC-E) and Powdermax (PW1)?

Powdermax (PW1)

Ascent Fume Hood (ADC-E)

Ventilated Balance Enclosure (VBE)

Application

Ideal for powder weighing / handling granules or particles

Ideal for handling solvents/solutions and chemicals in powdered form/particles/

- Usually recommended in cleanroom applicationsIdeal for powder weighing (can reach large scale) for non-sterile hazardous drug preparation.

- Provides containmentClassification

Powder weighing balance enclosure

Fume Hood

Containment ventilated enclosure

Exhaust Mode

Ductless or Ducted

Ductless

Ducted (standard) or ductless

Filter Module

HEPA only (N/A for carbon filter)

Main filter: Carbon

Exhaust filter: HEPASingle or dual HEPA filtration with option for carbon filter

Airflow Velocity

0.5 m/s

0.4 m/s

0.3 m/s

BIBO

No

No

Yes

_Brochure_A4_vA.webp)