Isoclean® Healthcare Platform Isolator - With Filter Below Workzone

Optimized Solution for Aseptic/Hazardous Applications

The Isoclean® Healthcare Platform Isolator (HPI-G3) facilitates the isolation of a product or process while providing the required aseptic/hazardous environment. It is factory-configured to operate at positive or negative pressure in single or recirculating airflow. This equipment provides a comprehensive range of personnel and product protection in addition to the surrounding work areas and the environment.

The positive pressure HPI-G3 model is suitable for work involving non-hazardous materials, while the negative pressure isolator is suitable for work involving hazardous materials e.g. cytotoxic compounding applications.

The work zone and pass chamber interchange are either under positive or negative pressure to the room to maintain sterility or operator protection, respectively, in case of a breach in the barrier isolation system.

Key Benefits:

Unidirectional airflow of 0.40 ± 20% m/s provides superior protection for highly sensitive product

Class 2 containment enclosure on manual pressure leak test as per ISO 10648-2

Suitable for various applications such as pharmacy compounding, small-scale potent material handling, sterility testing, aseptic processing, research and development, and cell processing

Centrifugal, direct-drive blowers designed for maximum energy efficiency and minimal maintenance

Sentinel™ Gold Microprocessor Control System supervises all functions and monitors airflow and pressures in real-time

Type D2 Pass Chamber as per ISO 14644-7 with interlocked doors, adjustable purged duration, and time-delayed ingress/egress control allowing sufficient time for surface decontamination to minimize transfer of contamination

Removable sliding tray (option for perforated or non-perforated) prevents operator fatigue during transfer procedures

Electromagnetic Interlocking Doors with time delay effect ensures safety and containment between the Pass Chamber and the Process Chamber

Return Filter (option to upgrade to safe change BIBO) below work zone filters the contaminated air immediately to minimize possibility of airborne contamination

Foot switch provides hands-free access to opening of the Pass Chamber inner door minimizing operator fatigue during transfer procedures

HEPA H14 filters with a typical efficiency of >99.995% at 0.1-0.3 microns provide superior ISO Class 3 air cleanliness

LED Lamps deliver >650 as per NSF49 to the work surface for superior overall illumination

With ISO Class 3 environment, the Process Chamber facilitates aseptic processing in an EU GMP Grade A condition

Circular glove ports (200 mm diameter) with minimal crevices, no exposed bolts and nuts

Frameless tempered glass front visor panel with highly rounded edges to minimize crevices and maximize door vision panel

Single or upgradable to multiple, removable work trays for easy surface cleaning and decontamination

Optional adjustable hydraulic stand, with casters wheels, elevates to accommodate user preference for sitting or standing work surface height

Relay contact/volt-free contact to send on/off status and general alarm to Building Management System (BMS)

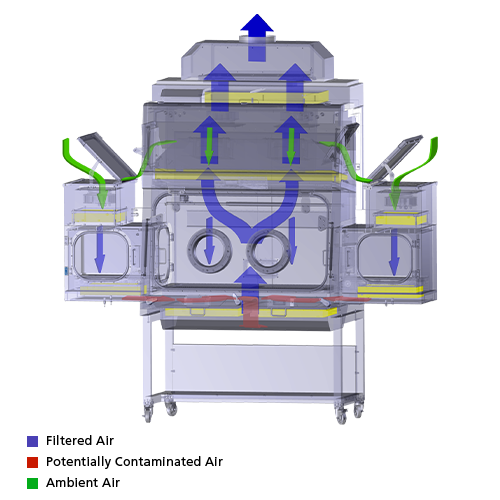

Ambient air is pulled through the inlet pre-filter (>60% efficiency as per EN 779 for positive pressure model) located on top of the isolator. The pre-filter traps large size particles to extend the life of the supply HEPA (H14) filter.

Air from the top inlet and from work zone is pulled by the fan, which creates positive pressure on the plenum that creates downflow. Work zone pressure is always higher than the pass-through, to prevent contaminants from entering the work zone through the pass-through.

The downflow filter creates a full unidirectional airflow and particle-free ISO Class 3 environment inside the isolator to protect the work material inside the main chamber and pass-through. Air from the work zone and pass-through is quickly purged by the fans to keep the area clean.

Note:

- ** Weight is a rough estimation, including support stand SHM. Contact Esco for more details

- * Add 260 mm height, with Top Exhaust Collar

- * No height difference with Carbon Filter

- * Adjustable hydraulic stand is not recommended for hard-ducted unit

Note: Tolerance for building exhaust requirement is 30%

Electrical outlets

UV Lamp

IV bars with hooks for handling bags

Exhaust collar

Carbon VOC with filter housing

Anti-blow back valve

CCTV and rear view adaptation

Motorized Hydraulic Stand Control

Fixed Support Stand with Caster Wheels or Leveling Feet

Telescopic Support Stand

Alarm Package for Audio and Visual Alarms

Mechanical Latches

Granite Slab with Stainless Steel 316L Leveling Feet and Frame

Manual Drain Valve

Manual Glove Leak Tester

Single- or Multi-piece tray option

Sharps container

Bag In or Bag Out (BIBO) 1st Exhaust Filter