Cell Processing Isolator: Choosing the Right Isolator for Cell Therapy

Cell processing is moving towards commercial production by scaling up

and through multiple means of increasing the capacity of laboratory processes. Automated

systems are now available for some of the cell manipulations that are

traditionally carried out manually. Some processes, however, still do not have

the available option for closed system automation.

The traditional means of using biosafety cabinets (BSCs) to provide

product and operator protection in this application are more commonly found and

suited in the initial research and development stage. However, the scale-up of

this equipment proposes a possible hurdle. Companies opt to have a room filled

with BSCs for multiple processes.

In a scale-up production, the environment in which cell therapies are handled must follow the current Good Manufacturing Practices (cGMP). There are two available options for the environment to isolate an aseptic biopharmaceutical process:

1.

An open system

like Biosafety Cabinet provides Grade A environment placed in a Grade B

Cleanroom.

2. A closed system like the Isolator delivers a Grade A environment in a Grade C or D Cleanroom.

These setups do not only mean an area of defined ventilation or

filtration system. It includes the specific type of gowning for the personnel,

regular training of personnel, and all the related standard operating

procedures (SOPs) carried out for the application.

Compared to traditional sterile pharmaceuticals, all cell therapy applications cannot be terminally sterilized. Therefore, rigorous quality control is paramount in production regardless of the batch size or product type. Whether it is a patient-specific autologous therapy or a large-volume batch of an allogeneic, off-the-shelf product, the entire process must be carried out aseptically. All the processes including final product quality control testing must be done in a manner and area that assures sterility and efficacy.

Considerations in Selecting the Right Isolator

The following factors are to be considered in deciding on the right

isolator:

1.

Process / Method

Cell processes or methods vary widely among different products. The

common cell expansion also makes use of different technologies. The isolator

must allow routine processes to be carried out in an efficient manner while

together eliminating the risk of contamination.

2.

Equipment

Integration Capability, Machinery, and Robotics

Depending on the process, the isolator’s physiological requirements and

design may vary. Isolators may be integrated with multiple sets of equipment

such as incubator, centrifuge, and microscope, among others.

The area of pharmaceuticals in which robotics are commonly used is in

the aseptic fill-finish process. Semi-automated or fully automated filling

machines may be integrated within an isolator system.

Note: Esco Pharma can customize isolators integrating the

client's process equipment. For more information, contact the local office near

you today.

3.

Ergonomics

Typically, cell therapy processes are carried out for a long-term

duration. The ergonomics of an isolator must allow manual manipulations to be

carried out efficiently and comfortably.

4.

Instrumentation

The design of the isolator must have the ability to pass samples and

data from all the instruments and equipment within the isolator and allow

connection into the possible building management system.

5.

Environment

Isolators can provide product, operator, and environment protection.

Depending on the characteristic of samples handled, an isolator may operate in

negative and/or positive pressure with a single pass or recirculating airflow

regime. It can be designed with a fully integrated bio-decontamination system.

It is also capable of providing special conditions such as an inert environment

and/or temperature and relative humidity-controlled system, depending on the

requirements.

Cell Processing Isolator

Esco Pharma’s Cell Processing

Isolator (CPI) is designed to

provide an ergonomic and practical cGMP compliant solution for the production

of cell therapies. The CPI is designed to isolate the process to ensure

operator safety, without compromising the product quality. It also provides the

unidirectional/laminar airflow delivering a sterile environment (ISO Class

5/Grade A) that is required in carrying out aseptic processes.

As a fully cGMP-compliant isolator and an aseptic containment system, it

is capable of automated pressure hold testing and of automated

bio-decontamination. It can also be equipped with a glove leak tester to allow

individual testing of the glove’s integrity. By standard, the internal material

of construction is made with stainless steel 316L equipped with passthrough

chambers. It may also be equipped with Rapid-Transfer-Ports (RTPs). This design

allows the introduction and removal of samples in a controlled material flow

without the risk of introducing contaminants into the internal chamber or

allowing the products to escape the isolator.

A CPI is also equipped with environmental monitoring capabilities such

as temperature sensors, relative humidity sensors, and pressure sensors.

Continuous particle monitoring systems and viable/microbial air samplers can

also be integrated.

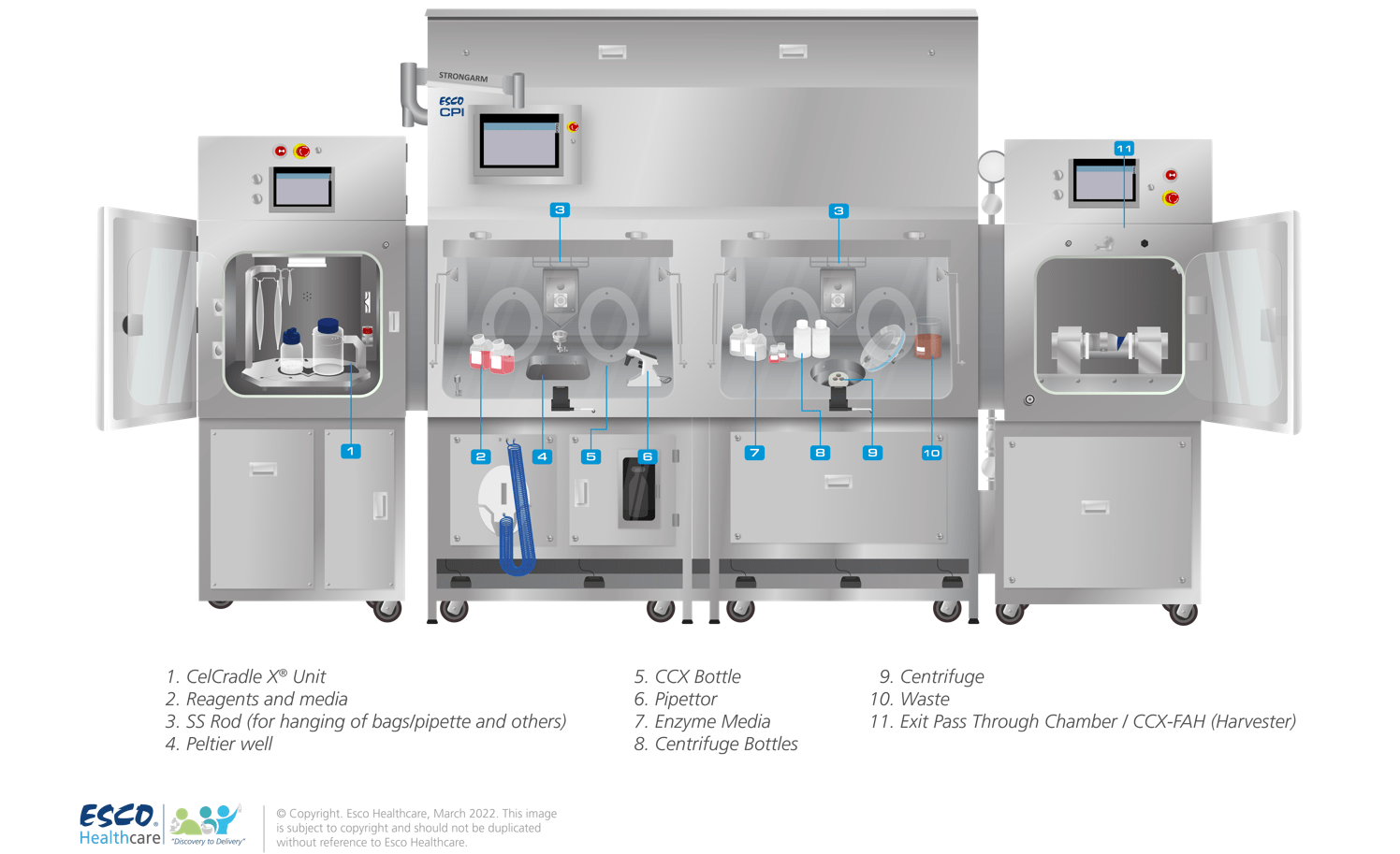

The CPI is an integrated system that can combine several types of equipment into one isolated solution. This setup offers increased sterility with a reduced risk of contamination, thus increasing patient safety. The CPI can be custom-designed to suit individual customer requirements (see Figure 1). Depending on the client’s requirements, the following are the common sets of equipment that are integrated into a CPI:

·

CO2 Incubator

·

Centrifuge

·

Microscope

·

Refrigerator

and/or Freezer

·

Peltier Wells

·

Bioreactor

·

Harvesting

Systems

·

Filtration

Systems

·

Laminar Airflow

Cabinet

·

Biosafety

Cabinet

· Laboratory Shaker

Figure 1. Cell Processing Isolator with fully integrated sets of equipment for full aseptic bioprocessing

Choosing the correct system like the cell processing isolator can

provide multiple advantages. As we develop and customize the equipment and the

processes. It is also critical to note that the cost and schedule are always

the major drivers in equipment selection. The key in the selection of an

isolator is to find a machine, process, and system that best fit your process

and product.

Cell therapies are capable of giving terminal patients an opportunity to

survive. At the end of the day, considerations must be made based on the added

value that a piece of equipment or upgrade brings about to one’s

services.

References:

1. Bozenhardt, H. (2020, April 16). Selecting The Right

Isolator For Cell Therapy Manufacturing: Considerations & Challenges.

Https://www.Cellandgene.Com/. Retrieved January 28, 2022, from

https://www.cellandgene.com/doc/

selecting-the-right-isolator-for-cell-therapy-manufacturing-considerations-challenges-0001

2. European Medicines Agency. Advanced therapy medicinal

products: Overview. (2021, December 3). Retrieved February 5, 2022, from

https://www. ema.europa.eu/en/human-regulatory/overview/

advanced-therapy-medicinal-products-overview

3. Meyer, D. (2021, May 27). Individual closed isolators

for cell therapy. A3P - Pharmaceutical & Biotechnology Industry. Retrieved

February 12, 2022, from https://www.a3p.org/en/ closed-isolators-cell-therapy/

4. US Food and Drug Administration. Guidance for Industry

Sterile Drug Products Produced by Aseptic Processing – Current Good

Manufacturing Practice, US Department of Health and Human Services. Rockville,

Md., 2004. https://

www.cellandgene.com/doc/selecting-the-right-isolator-for-cell-therapy-manufacturing-considerations-challenges-0001