BioBooth®

Esco’s BioBooth® is similar to a Biological Safety Cabinet Class II which can provide an ISO Class 5 work environment to house relatively larger research devices, apparatus, equipment, machineries and operating robotics under appropriate controlled cleanroom conditions.

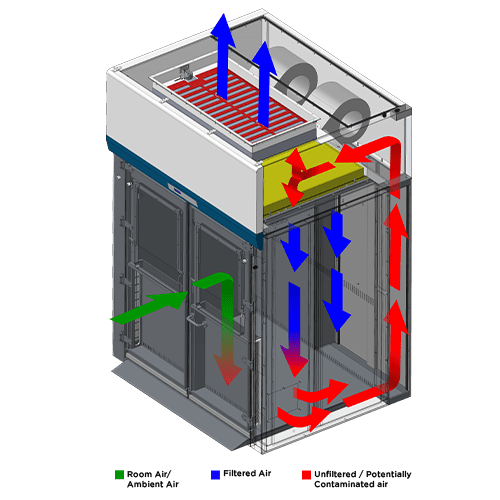

The BioBooth® utilizes airflow design mechanism which allows adequate control on the inflow and exhaust of air, ensuring operator, product, and environmental protection.

ISO Class 5 air cleanliness as per ISO 14644-1

HEPA (H14) filter as per EN 1822 with a typical efficiency of >99.995% at 0.1 to 0.3 microns

Electronic Door Lock

Electrogalvanized steel finish with ISOCIDE™ antimicrobial coating construction

Esco Sentinel™ Gold Microprocessor Controller with audio/visual alarms for downflow velocity differential pressure across filters

Stainless steel easy-to-clean interior work surfaces

Side door access and ports for caps and bottle entry

Viewing hinged window

Permanently lubricated direct drive centrifugal blowers

Front air capture and rear grilles

Airflow sensor

Filter life display

Monitoring system of airflow and proper enclosure conditions

LED lighting

Filtration System

Ambient air is pulled through the perforations located in front of the work zone front to prevent contamination of the work surface and product. The inflow does not mix with the clean air within the cabinet work zone. Inflow air travels through a return path toward the common air plenum (blower plenum) at the top of the cabinet.

Approximately 37% of the air in the common plenum is exhausted through the HEPA filter to the room. The remaining 63% of the air is passed through the downflow HEPA filter and into the work area as a vertical laminar flow air stream, bathing the work surface in clean air.

The uniform, laminar/unidirectional air stream protects against cross-contamination within and throughout the work area.

Near the work surface, the downflow air stream splits with a portion moving toward the front air grille, and the remainder moving to the rear air grille.

A combination of inflow and downflow air streams form an air barrier that prevents contaminated room air from entering the booth, and prevents work surface emissions from escaping the work zone. Air returns to the common air plenum where the 37% exhaust and 63% recirculation process is continued

|

General Specifications |

||

|

Model |

BioBooth® |

|

|

External

Dimensions (W x D x H) |

1840 mm x 1580 mm x 2510 mm (72.4" x 62.2" x

98.8") |

1840 mm x 1352 mm x 2220 mm (72.4" x 53.2" x

87.4") |

|

Internal

Work Area, Dimensions (W x

D x H) |

1480 mm x 1068 mm x 1810 mm (58.3" x 42" x

71.3") |

1480 mm x 868 mm x 1570 mm (58.3" x 34.2" x

61.8") |

|

External

Construction |

Electrogalvanized steel with

white oven-baked epoxy-polyester ISOCIDE™ antimicrobial powder-coated finish,

1.5 mm (0.06") / 16 gauge thick |

|

|

Internal

Constuction |

Stainless steel Type 304 with

No.4 finish, 1.5 mm (0.06") / 16 gauge thick |

|

|

Downflow

Velocity |

0.30 m/s ± 20% |

|

|

Inflow

Velocity |

0.5 m/s ± 5% |

|

Stainless steel worktop with caster wheels

UV lamp

Electrical ports

Decontamination port

Reinforced base with ramp to facilitate wheeled-cart transfers