Isoclean® Healthcare Platform Isolator - Inflatable Seal – BioVap™ (HPI-IS-BVP)

Optimized Solution for Sterile/Aseptic Applications

The Isoclean® Healthcare Platform Isolator – Inflatable Seal - BioVap™ Model (HPI-IS-BVP) ensures the isolation of a product/process while providing the required ISO Class 5 / Grade A environment.

HPI-IS-BVP is equipped with inflatable seals and automated dampers. As standard, the standard unit is fully integrated with both the auto-pressure hold testing and BioVap™ (hydrogen peroxide biodecontamination system with H2O2 sensors and catalytic converter).

Integration of Esco BioVap™ allows both master and independent biodecontamination process of main chamber and pass-through chambers (PTCs). This improved design facilitates ease of isolation control especially during pressure decay testing and bio-decontamination process.

This model can be adjusted on-site to operate in positive or negative pressure regime. It is also available in recirculating or total exhaust configuration.

Applications:

- Aseptic and/or Potent Compounding

- Pharmacy Compounding

- Sterility Testing

- Cell and Gene Therapy

- Peptide Production

- Biosafety Facility Level 3 or 4

- Benchtop/Small-scale Aseptic Formulation and Filling

- Small-scale Potent Material Handling

- Cosmeceutical

- R&D and Clinical Trials

- This model is capable of expanding up to 3 modules of 2-glove main chamber with 2 modules of pass-through chamber (left and right).

- Capable of automated pressure hold testing (APHT) and biodecontamination with log 6 reduction in bioburden.

- HEPA (H14) filter (as per EN 1822) with a typical efficiency of > 99.999% at 0.1 to 0.3 microns; provide superior ISO Class 5 air cleanliness as per ISO 14644-1.

- Containment enclosure classification: Class 2 as per ISO 10648-2.

- Electromagnetic interlocking doors with time delay effect ensures safety and containment during material transfer.

* With built-in air compressor to support inflatable seals in the window and dampers, and the BioVap™ biodecontamination system.

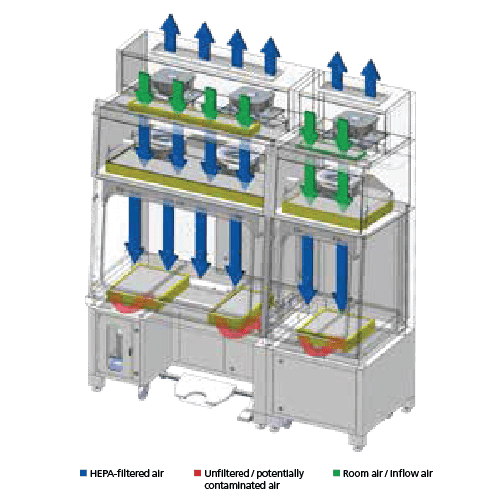

Single Pass/Total Exhaust Configuration

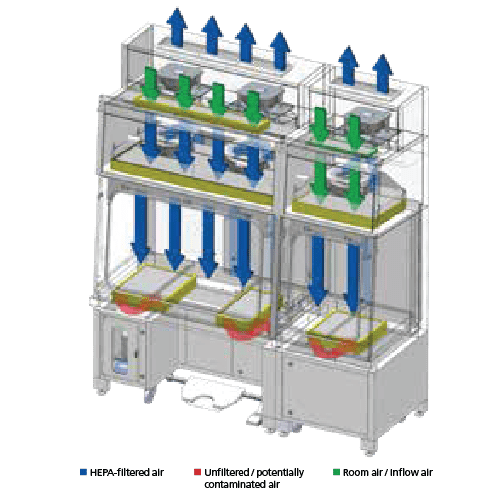

Recirculating Configuratiom

|

ISOCLEAN® |

2-glove Main Chamber |

3-glove Main Chamber |

4-glove MainChamber |

Passthrough Chamber |

3-way Passthrough Chamber |

|

|

External Dimension (W x D x H) |

1340 x 800 x 2350 mm |

1645 x 800 x 2350 mm |

1950 x 800 x 2350 mm |

730 x 800 x 2350 mm |

730 x 800 x 2350 mm |

|

|

Internal Dimension (W x D x H) |

1290 x 620 x 700 mm |

1595 x 622 x 700 mm |

1900 x 622 x 700 mm |

680 x 620 x 700 mm |

680 x 620 x 700 mm |

|

|

Passthrough Chamber - Tray Dimension |

N/A |

N/A |

N/A |

270 x 660 mm |

270 x 660 mm |

|

|

Isolator Construction |

External Body |

ISOCIDE™ Powder-coated electrogalvanized steel |

||||

|

Internal Chamber |

Stainless steel 316L |

|||||

|

Airflow |

Unidirectional/Laminar Airflow |

|||||

|

Process Chamber Pressure |

+37 Pa |

+25 Pa |

||||

|

Selectable between -60 Pa to +75 Pa |

||||||

|

Process Chamber Downflow Velocity |

0.45 m/s +/-20% |

|||||

|

Chamber Lighting |

Normal Operating Mode |

Warm White, Minimum 500 Lux |

no lighting for PTC Module |

|||

|

Bio-decontamination Mode |

Blue |

no lighting for PTC Module |

||||

|

Alarm Mode |

Red |

no lighting for PTC Module |

||||

|

Aeration Mode |

With Integrated Catalytic Converter |

|||||

|

Pressure Hold Test |

During FAT and IQOQ |

Class 2 Containment as per ISO 10648-2 |

||||

|

Automated Daily Routine |

Class 3 Containment as per ISO 10648-2 (Pressure hold test prior to each biodecontamination |

|||||

|

Net Weight |

525 Kg |

650 Kg |

|

328 Kg |

|

|

|

Inflatable Sealed Side Adaptor Plate/ Retrofit Option |

RTP for sizes 105 mm, 190 mm, or 270 mm |

N/A |

||||

|

Up to 4 x 1” Tri-clover connection |

N/A |

|||||

- Available in Recirculating or Total Exhaust configuration

- Integration of a side-mounted CO2 Incubator

- Glove Leak Tester

-

Glove Port sizes

- 300 x 300 mm

- 300 x 200 mm

- CCTV integration

- Access to rear view monitor system

- Addition of sterility test pump

- Mechanical integration of viable/non-viable particle monitoring (with separate software)