Containment Barrier Isolator - III (CBI-III)

Your Practical Solution to cGMP Compliance

Containment Barrier Isolator - Class III Biosafety Cabinet (CBI-III) offers the highest level of operator, product, and environmental protection from infectious/biohazardous aerosols and is suitable for microbiological work with agents assigned to biosafety levels 1,2,3, or 4. It is designed for an absolute level of containment, it is frequently used for work involving the deadliest biohazards, bacteria, viruses, and microorganisms.

CBI-III is configured to operate at a minimum of -125 Pa to provide adequate containment for handling highly pathogenic and lethal biological agents.

Applications:

Laboratory containment for handling biological agents of up to level 4

Virus and vaccine production

Cell Processing

Research and development

Fully welded stainless steel 316L internal chambers with stainless steel 304 external housingg

Exhaust air is double-filtered through high-quality ULPA filters (per IEST-RP-CC-001.3) with typical efficiency of >99.999% for 0.1 to 0.3 micron particles, better than HEPA filters.

An integrated pass-through with interlocking doors permits materials transfer without risk of contamination

Single-piece, leak-tested glove assemblies which guarantee maximum protection.

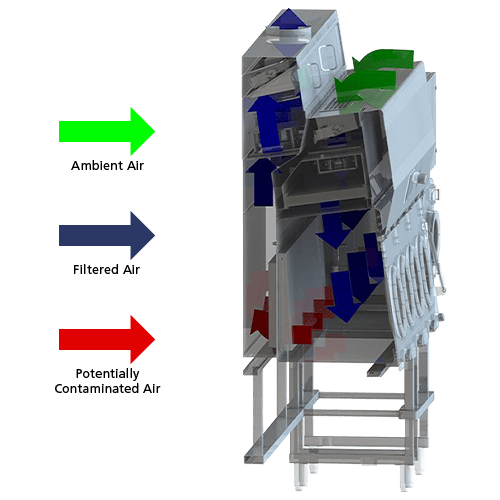

Ambient air is pulled through the inlet prefilter located on top of the isolator. Air from the top inlet and from work zone is pulled by the fan which creates a positive pressure on the plenum that creates downflow. The HEPA (H14) downflow filter creates a laminar and particle-free ISO Class 5 air cleanliness as per ISO 14644-1 (equivalent to Class 1 as per US Fed Std 209E) inside the isolator to protect the work material inside the main chamber and pass-thru. Air from the work zone and pass-thru is quickly purged out by the fan to keep the area clean. The fan pulls approximately 90% of the purged air back to the plenum and after passing through the HEPA (H14) downflow filter.

The high rate of airflow recirculation helps to prolong filter life and reduces the chances of ambient contaminants entering the work zone. For a recirculating model, approximately 10% of the purged air is exhausted through an HEPA-filter to prevent heat build-up inside the isolator that can be detrimental to drug compounding. This exhausted air is replenished by ambient air coming from the top inlet prefilter and a filter with 80% efficiency for positive pressure model. For a Total Exhaust/Single-Pass Model, 100% of the air is exhausted out of the isolator.

|

GENERAL SPECIFICATIONS Containment Barrier Isolator - Class III Biosafety Cabinet |

CBI-III-2G |

CBI-III-3G |

CBI-III-4G |

|

|

Main Chamber Nominal Size (Width) |

1.2 meter (4’) |

1.6 meter (5.2’) |

2.0 m (6.6’) |

|

|

Working Chamber Dimensions - Min (W x D x H) |

1.2 m x 0.55 m x 0.77 m |

1.6 m x 0.55 m x 0.77 m |

2.0 m x 0.55 m x 0.77 |

|

|

Working Chamber Dimensions - Max (W x D x H) |

1.2 m x 0.63 m x 0.84 m |

1.6 m x 0.63 m x 0.84 m |

2.0 m x 0.63 m x 0.84 m |

|

|

External Dimension |

With Adjustable Base Stand (Min) |

1.82 m x 0.92 m x 2.55 m (6.0’ x 3.0’ x 8.4’) |

2.22 m x 0.92 m x 2.55 m (7.3’ x 3.0’ x 8.4’) |

2.62 m x 0.92 m x 2.55 m (8.6’ x 3.0’ x 8.4’) |

|

With Adjustable Base Stand (Max) |

1.82 m x 0.92 m x 2.85 m (6.0’ x 3.0’ x 9.4’) |

2.22 m x 0.92 m x 2.85 m (7.3’ x 3.0’ x 9.4’) |

2.62 m x 0.92 m x 2.85 m (8.6’ x 3.0’ x 9.4’) |

|

|

External Dimension -Small Pass-through Chamber (W x D x H) |

0.60 x 0.52 x 0.76 m |

|||

|

Glove Port Height (Min) |

1000 mm |

1000 mm |

1000 mm |

|

|

Glove Port Height (Max) |

1300 mm |

1300 mm |

1300 mm |

|

|

Chamber Environment |

ISO Class 5 all chambers (Grade A) |

|||

|

Pre-filter |

Process Chamber |

G4, polyester media |

||

|

Pass-through Chamber |

G4, polyester media |

|||

|

Filter Type - Chamber Inlet |

HEPA (H14) Filter with Integral Mesh Guard and Gasket Seal |

|||

|

Filter Efficiency - Chamber Inlet |

99.995% MPPS |

|||

|

Filter Type - Chamber Exhaust |

HEPA (H14) Filter with Integral Mesh Guard and Gasket Seal |

|||

|

Filter Efficiency - Chamber Return and Exhaust |

99.995% MPPS |

|||

|

Lighting Level |

≥ 500 Lux (6000 K) |

|||

|

Sound Level |

≤ 80 dBA |

|||

|

Airflow Type |

Unidirectional/ Laminar Airflow |

|||

|

Chamber Operating Pressure |

negative 125 Pa |

|||

|

Isolator Construction |

Chamber |

SS 316L |

||

|

Service Housing |

SS 304 |

|||

|

Support Frame |

SS 304 |

|||

|

Isolator Finish |

Chamber Internal |

≤ 0.4 Ra |

||

|

Chamber External |

≤ 0.6 Ra |

|||

|

Serivce Housing External |

≤ 0.6 Ra |

|||

|

Support Frame |

≤ 1.0 Ra |

|||

|

Electrical Requirements |

220-240 VAC, |

CBI-3-2G8 |

CBI-3-3G8 |

CBI-3-4G8 |

|

(by Client) |

110-120 VAC, |

CBI-3-2G9 |

CBI-3-3G9 |

CBI-3-4G9 |

|

Compressed Air Requirement (by Client) |

2 Bar-g Pressure at 5 L/sec |

✔ |

✔ |

✔ |

|

Exhaust Duct Requirements (by Client) |

10 “ Duct from Isolator to Outside |

|||

|

Air Change per Hour |

1570 ACH |

1570 ACH |

1570 ACH |

|

|

Volumetric Flow Rate |

916 cmh |

1225 cmh |

1532 cmh |

|

|

Downflow Velocity |

0.4 m/s |

|||

|

Net Weight |

TBD |

TBD |

TBD |

|

|

Shipping Weight |

TBD |

TBD |

TBD |

|

|

Shipping Dimension (W x D x H) |

TBD |

TBD |

TBD |

|

|

Shipping Volume (Maximum) |

TBD |

TBD |

TBD |

|

| LIST OF OPTIONS for CBI Models | CBI-U | CBI - T | CBI-III | CBI-H | |||

| 4" Split Butterfly Valve (for powder discharge of powder below isolator chamber) | ✔ | ✔ | |||||

| Adjustable Hydraulic Stand (based on operator ID input) | ✔ | ✔ | ✔ | ||||

| Exhaust Box (with automated dampers with inflatable seals or manual with valve) | ✔ | ✔ | ✔ | ||||

| Anti-blow back damper box | ✔ | ✔ | ✔ | ||||

| Automated Pressure Hold Test | with Client Supplied Compressed Air | ✔ | ✔ | ✔ | ✔ | ||

| with On-board Air Compressor | ✔ | ✔ | ✔ | ✔ | |||

| Bag Welder with Table Bag-out Port |

✔ | ✔ | ✔ | ||||

| Bio Dunk Tank Bag Out Port |

✔ | ✔ | |||||

| Mobile Biodecontamination BioVap TM | ✔ | ✔ | ✔ | ||||

| Carbon Filter | ✔ | ||||||

| Convertible to Class 1 cabinet | ✔ | ||||||

| Integration of small scale aseptic or potent tablet/capsule etc… | ✔ | ✔ | ✔ | ✔ | |||

| Double-sided access | ✔ | ✔ | ✔ | ||||

| Manual Drain Ball Valve (for client controlled CIP/WP) must order with inner pass-through inflatable sealed doors. | ✔ | ✔ | |||||

| Electrical Outlet (IP66) | IP 66 | ✔ | ✔ | ✔ | ✔ | ||

| ATEX Zone 1/21 (only for internal environment) | ✔ | ✔ | ✔ | ||||

| ATEX rating up to zone 1/21 internally only (ATEX fan, “IS” signals for internal door sensor/push button) | ✔ | ✔ | |||||

| Glove Leak Tester | ✔ | ✔ | ✔ | ✔ | |||

| Formalin Vaporizer (auto neutralization and purge cycle) | ✔ | ✔ | ✔ | ||||

| H2O2 Monitoring (sensor is not integrated with HMI) | ✔ | ✔ | ✔ | ||||

| Liquid Water Entry / Exit Ports | ✔ | ✔ | |||||

| N2 Purge for Process Chamber | ✔ | ||||||

| Ø250 mm Product Waste Bag Out Ports / | ✔ | ||||||

| Battery option to maintain EM interlock during power outage or E Stop | ✔ | ✔ | ✔ | ✔ | |||

| Particle Counter | Portable Paricle Counter (Non-viable) | ✔ | ✔ | ✔ | |||

| Microbial Air Samples (Viable Particle Counter) | ✔ | ✔ | ✔ | ||||

| Product Waste Entry / Exit Ports | ✔ | ✔ | |||||

| RTPØ 105, 190, 270 - Alpha | ✔ | ✔ | ✔ | ✔ | |||

| RTPØ 105, 190, 270 - Beta Canister | ✔ | ✔ | |||||

| RTPØ 105, 190, 270 - Beta Liner | ✔ | ✔ | |||||

| RTPØ 350, 460 - Alpha, Beta Liner, Beta Canister | ✔ | ✔ | ✔ | ||||

| Service Fixtures (Vacuum, Nitrogen, Compressed Air, Nozzle for BioVap) | ✔ | ✔ | ✔ | ✔ | |||

| Spray Ball (CIP) with Manual Ball Valve | ✔ | ||||||

| Spray Gun (WIP) with Manual Ball Valve | ✔ | ✔ | |||||

| Sterile Continuous Liner | ✔ | ✔ | ✔ | ||||

| Sterility Test Pump | ✔ | ||||||

| Temperature and Relative Humidity Monitoring (only for process chamber) | ✔ | ✔ | ✔ | ✔ | |||

| Rear view monitor | ✔ | ✔ | ✔ | ✔ | |||

| UV Lamp | ✔ | ✔ | |||||

| Weighing Scale Granite Slab | ✔ | ✔ | ✔ | ||||

| Sharps (inside) | ✔ | ||||||