Infinity® Esco Air Shower Pass Box (EAS-PB)

The Esco Air Shower Pass Box (EAS-PB) is a cost-effective solution for controlling the ingress of contamination into cleanrooms and their surrounding facilities. Its high-velocity HEPA-filtered air jets ensure that all materials are scrubbed off possible particulates that might affect the sterility of the process and final products.

Key Benefits:

Energy Efficient

SS 304 nozzles

SS 304 base surface

Acrylic doors

Disposable prefilter

-

Built-in air shower significantly reduces surface contamination on materials entering or exiting the controlled environment

-

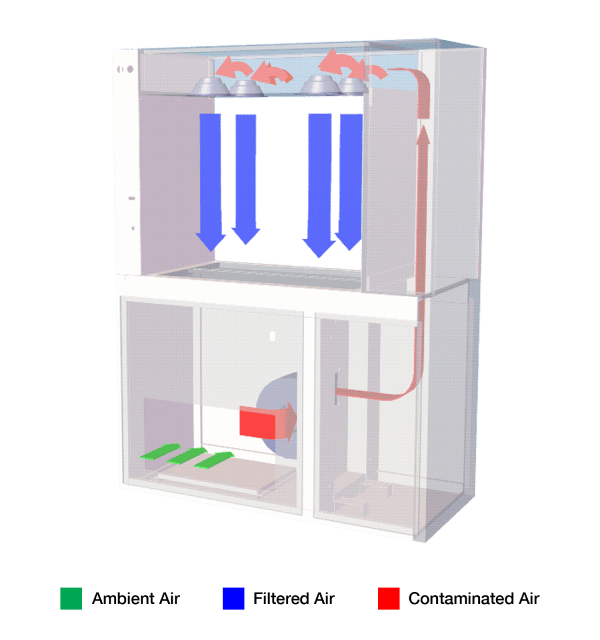

Materials entering or exiting the controlled environment are “scrubbed” by high velocity HEPA-filtered air jets with velocities of 18-30 m/s (3,543-5,906 fpm)

Contaminated air is then drawn through the base within the unit, filtered, and recirculated

-

An array of stainless-steel nozzles directs high-velocity jets within the chamber

Air shower duration is adjustable up to 2 mins. Standard factory pre-set is 12 seconds.

Electrical interlocking door mechanism

The air shower is constructed of electrogalvanised steel swith white oven-baked epoxy-polyester Isocide™ antimicrobial powder coated finish

The pass box base surface is constructed of perforated stainless steel 304, making it easy to clean

Polycarbonate viewing windows provide a clear view of the internal chamber

-

Esco Air Shower Pass Boxes use German made ebm-papst® permanently lubricated, centrifugal motor/blowers with external rotor designs

Selected for energy efficiency, compact design, and flat profile, the completely integrated blower assembly optimizes motor cooling, with unified rotating parts and overall component balance for smooth, quiet, vibration-free operation

Air is forced by the blower(s) through HEPA filter(s) which are >99.995% efficient against particles of 0.3 microns.

Filtered air is ejected through nozzles at high velocities into the chamber. These turbulent air streams disperse particulate matter on all surfaces.

Dispersed particulate matter migrate with the air stream towards the lower areas in the air shower chamber.

The air is continuously filtered and recirculated.

| General Specifications, Esco Air Shower Pass Box | |||

| Model | EAS-PB | ||

| Model Code | EAS-PB | EAS-PB-SS | |

| External Dimensions (W x D x H) | 1120 x 540 x 1500 mm (44.1” x 21.3” x 59.0”) | ||

| Internal Work Area, Dimensions (W x D x H) | 800 x 500 x 600 mm (31.5” x 19.7” x 23.6”) | ||

| Material of Construction (MoC) | Body | Powder-coated EG Steel exterior and interior | Full stainless steel 304 |

| Viewing Window | Polycarbonate | ||

| Base | Perforated stainless steel 304 base | ||

| Door Opening | Straight through only | ||

| Door Lock System | Electromagnetic Interlock | ||

| Air Change | 1360 / hr | ||

| Air Velocity (m/s) | 18-30 m/s (3,543-5,906 fpm) | ||

| Number of Nozzles | 4 | ||

| Air Shower Duration (seconds) | Factory set at 12 seconds (adjustable up to 2 mins) | ||

| Prefilter | G4 Pre-filter, Washable non-woven polyester fibers with an efficiency 90% | ||

| Main Filter | H14 HEPA Filter, Efficiency 99.995% at Most Penetrating Particle Size (MPPS) as per EN1822:2009 | ||

| Electrical * | Voltage | 220 - 240 V, AC, 50 Hz, 1ø | |

| Cabinet Full Load Amps (FLA) | 1.75 A | ||

| Cabinet Nominal Power | 250 W | ||

| Cabinet BTU | 853 | ||

| Net Weight | 130 kg (286 lbs) | ||

| Shippping Weight | 164.3 kg (362 lbs) | ||

| Shipping Dimensions, Maximum (W x D x H) | 1120 x 570 x 1650 mm (44.1” x 22.4” x 65.0”) | ||

| Shipping Volume, Maximum | 1.05 m3 (37 ft3) | ||

-

Optional UV lamp

Full stainless steel construction