Soft Capsule® Soft Wall Cleanroom

The ideal solution when clean air areas need to be created on a small to mid scale. Flexible and economical, they may be easily relocated when application requirements change.

Applications:

Pharmaceuticals, Grade A filling suites

Medical devices, plastic injection moulding

Electronics assembly

Contact lens packaging

Hospital pharmacy (USP 797)

Biotechnology

Nanotechnology

Life sciences

Aerospace

Quality control

Food industries

Cleanroom ceiling grid enables flexible placement of fan filter units. Non-particulate shedding powder coated steel panels are provided to cover empty bays.

Provides ISO Class 5, 6, or 7 environments (depending on client specifications) via high quality HEPA filters utilizing an improved mini-pleated separation technique to maximize surface area, improve efficiency, and extend the filter life.

Centrally mounted control panel enables rapid start-up of fan filter units and lighting.

ESCO Airstream Fan Filter Units incorporate German made EBM-PAPST permanently lubricated, direct drive, centrifugal blowers with external rotor designs, and Swedish CAMFILL-Farr HEPA filters.

The energy efficient external rotor motor design reduces operating costs and has extremely low noise and vibration levels, improving the working conditions in the cleanroom.

High quality HEPA filters utilizing an improved mini-pleated separation technique to maximize surface area improves efficiency and extends the filter life. HEPA filters operate at a typical efficiency of >99.995% at 0.1 to 0.3 micron sizes.

An additional disposable pre-filter traps large particles in the inflow air prior to reaching the main filter, protecting against damage, and prolonging life.

A built-in solid-state variable speed controller is superior to conventional "step" controllers and offers infinite adjustment.

Isostat™ vinyl curtains isolate the cleanroom from the ambient environment, while allowing easy passage of materials and personnel in and out of the cleanroom area.

Stainless steel swivel casters feature non-shedding polyurethane wheels (capacity: 300 lbs each).

Cleanroom grade construction utilizing fully welded, reinforced, steel tubular sections. Structure is finished with an abrasion-resistant oven-baked powder coat.

The entire structure is free-standing and does not require any suspending ceiling supports.

Built-in warm white, 5000k lighting provides excellent illumination of the cleanroom, and reduces operator fatigue.

The Soft Capsule Cleanroom is shipped unassembled with tools and parts for on-site assembly, turning an existing air-conditioned space into a cleanroom in a matter of hours.

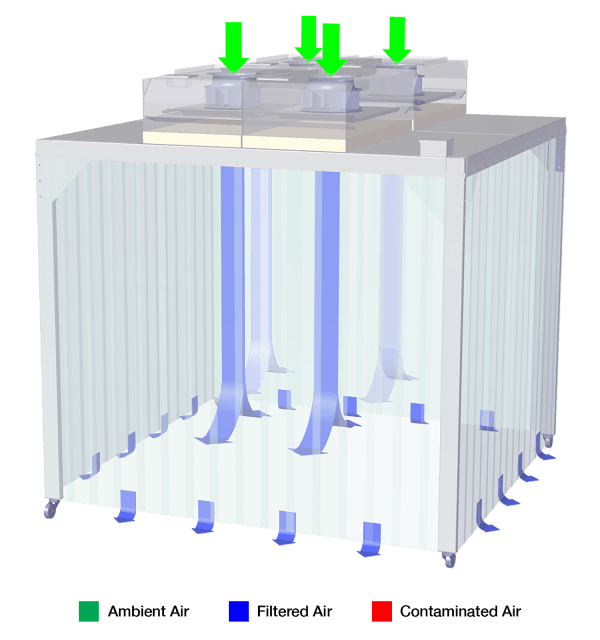

Room air is taken in from the top of the cleanroom through a disposable pre-filter with 90% efficiency; this serves to trap larger particles and increase the life of the main filter.

Air is forced evenly across the HEPA filter(s); the result is a stream of clean laminar air within the work zone; this dilutes and flushes all airborne contaminants from the interior.

A nominal filter face velocity of 0.45 m/s or 90 fpm ensures that there is a sufficient number of air changes within the cleanroom in order to maintain cleanliness.

The purified air travels downward within the interior in a vertical, unidirectional stream, and leaves the cleanroom close to floor level at the perimeter.

The cleanroom is positively pressurized to prevent ingress of airborne contaminants from the external environment.

|

General

Specifications, Soft Capsule Soft Wall Cleanroom, Model SC |

||||||||

|

Cleanroom Class |

Model |

Internal Dimension (W x D x H) |

External Dimension (W x D x

H) |

Power Consumption |

No. of FFUs |

Air Volume |

Shipping Dimension (W x D x

H) (Unassembled) |

Shipping Volume |

|

ISO Class 5* (US Federal

Standard Class 100) |

SC-447-M3.5 |

4’ x 4’ x 7’ |

4.23’ x 4.23’ x 8.60’ |

460 W |

2 |

2300 m³/h (1360 cfm) |

8.2’ x 2.46’ x 1.44’ |

0.825 m³ |

|

SC-487-M3.5 |

4’ x 8’ x 7’ |

4.23’ x 8.23’ x 8.60’ |

500 W |

2 |

2300 m³/h (1360 cfm) |

8.2’ x 4.1’ x 1.31’ |

1.25 m³ |

|

|

SC-687-M3.5 |

6’ x 8’ x 7’ |

6.30’ x 8.23’ x 8.60’ |

790 W |

3 |

3450 m³/h (2040 cfm) |

8.2’ x 4.1’ x 1.97’ |

1.87 m³ |

|

|

SC-6127-M3.5 |

6’ x 12’ x 7’ |

6.26‘ x 12.26’ x 8.60’ |

1210 W |

5 |

5750 m³/h (3400 cfm) |

12.8’ x 5.51’ x 1.48’ |

2.94 m³ |

|

|

SC-6167-M3.5 |

6’ x 16’ x 7’ |

6.26 ‘x 16.29’ x 8.60’ |

1420 W |

6 |

6900 m³/h (4080 cfm) |

8.2’’ x 4.1’ x 2.46’ |

2.34 m³ |

|

|

SC-6207-M3.5 |

6’ x 20’ x 7’ |

6.26' x 20.32' x 8.60' |

2000 W |

8 |

9200 m³ /h (5440 cfm) |

10.5' x 3.12' x 2.46' |

2.28 m³ |

|

|

SC-887-M3.5 |

8’ x 8’ x 7’ |

8.29' x 8.29' x 8.60' |

1080 W |

4 |

4600 m³ /h (2720 cfm) |

8.2' x 3.12' x 1.8' |

1.31 m³ |

|

|

SC-8107-M3.5 |

8’ x 10’ x 7 |

8.23' x 10.32' x 8.60' |

1370 W |

5 |

5750 m³ /h (3400 cfm) |

10.5' x 3.12' x 1.97' |

1.82 m³ |

|

|

SC-8127-M3.5 |

8’ x 12’ x 7’ |

8.29' x 12.26' x 8.60' |

1500 W |

6 |

6900 m³ /h (4080 cfm) |

12.47' x 3.02' x 1.64’ |

1.75 m³ |

|

|

SC-8167-M3.5 |

8’ x 16’ x 7’ |

8.29' x 16.29' x 8.60' |

1920 W |

8 |

9200 m³ /h (5440 cfm) |

8.53' x 3.12' x 2.43' |

1.84 m³ |

|

|

SC-8207-M3.5 |

8’ x 20’ x 7’ |

8.29'' x 20.32' x 8.60' |

2580 W |

10 |

11500 m³ /h (6800 cfm) |

10.5' x 3.12' x 2.3' |

2.91 m³ |

|

|

SC-10127-M3.5 |

10’ x 12’ x 7’ |

10.32' x 12.26' x 8.60' |

2210 W |

9 |

10350 m³ /h (6120 cfm) |

11.02' x 4.27' x 1.8' |

2.4 m³ |

|

|

SC-12127-M3.5 |

12’ x 12’ x 7’ |

12.36' x 12.36' x 8.60' |

2290 W |

9 |

10350 m³ /h (6120 cfm |

13.06' x 3.12' x 2.3' |

2.65 m³ |

|

|

ISO Class 6* (US Federal Standard Class

1000) |

SC-6127-M4.5 |

6’ x 12’ x 7’ |

6.26' x 12.26' x 8.60' |

790 W |

3 |

3450 m³ /h (2040 cfm) |

12.8' x 5.51' x 1.48' |

2.94 m³ |

|

SC-6167-M4.5 |

6’ x 16’ x 7’ |

6.26' x 16.29' x 8.60' |

1000 W |

4 |

4600 m³ /h (2720 cfm) |

8.2' x 4.1' x 2.46' |

2.34 m³ |

|

|

SC-6207-M4.5 |

6’ x 20’ x 7’ |

6.26' x 20.32' x 8.60' |

1080 W |

4 |

4600 m³ /h (2720 cfm) |

10.5' x 3.12' x 2.46' |

2.28 m³ |

|

|

SC-887-M4.5 |

8’ x 8’ x 7’ |

8.29' x 8.29' x 8.60' |

660 W |

2 |

2300 m³ /h (1360 cfm) |

8.2' x 3.12' x 1.8' |

1.31 m³ |

|

|

SC-8107-M4.5 |

8’ x 10’ x 7’ |

8.23' x 10.34' x 8.60' |

950 W |

3 |

3450 m³ /h (2040 cfm) |

10.5' x 3.12' x 1.97' |

1.82 m³ |

|

|

SC-8127-M4.5 |

8’ x 12’ x 7 |

8.29' x 12.26' x 8.60' |

870 W |

3 |

3450 m³ /h (2040 cfm) |

12.47' x 3.02' x 1.64 |

1.75 m³ |

|

|

SC-8167-M4.5 |

8’ x 16’ x 7’ |

8.29' x 16.29' x 8.60' |

1080 W |

4 |

4600 m³ /h (2720 cfm) |

8.53' x 3.12' x 2.43' |

1.84 m³ |

|

|

SC-8207-M4.5 |

8’ x 20’ x 7’ |

8.29' x 20.32' x 8.60' |

1620 W |

6 |

6900 m³ /h (4080 cfm) |

10.5' x 3.12' x 2.3' |

2.91 m³ |

|

|

SC-10127-M4.5 |

10’ x 12’ x 7’ |

10.32' x 12.26' x 8.60' |

1580 W |

6 |

6900 m³ /h (4080 cfm) |

11.02' x 4.27' x 1.8' |

2.4 m³ |

|

|

SC-12127-M4.5 |

12’ x 12’ x 7’ |

12.36' x 12.36' x 8.60' |

1450 W |

5 |

5750 m³ /h (3400 cfm) |

13.06' x 3.12' x 2.3' |

2.65 m³ |

|

|

SC-12167-M4.5 |

12’ x 16’ x 7’ |

12.36' x 16.29' x 8.60 |

2080 W |

8 |

9200 m³ /h (5440 cfm) |

12.8' x 3.12' x 2.3' |

2.59 m³ |

|

|

SC-12207-M4.5 |

12’ x 20’ x 7’ |

12.36' x 20.32' x 8.60' |

2080 W |

8 |

9200 m³ /h (5440 cfm) |

13.12' x 2.95’ x 2.3' |

2.52 m³ |

|

|

ISO Class 7* (US Federal

Standard Class 10,000) |

SC-6127-M5.5 |

6’ x 12’ x 7’ |

6.26' x 12.26' x 8.60' |

370 W |

1 |

1150 m³ /h (680 cfm) |

12.8' x 5.51' x 1.48' |

2.94 m³ |

|

SC-6167-M5.5 |

6’ x 16’ x 7’ |

6.26' x 16.29' x 8.60' |

500 W |

2 |

2300 m³ /h (1360 cfm) |

8.2' x 4.1' x 2.46' |

2.34 m³ |

|

|

SC-6207-M5.5 |

6’ x 20’ x 7’ |

6.26' x 20.32' x 8.60' |

660 W |

2 |

2300 m³ /h (1360 cfm) |

10.5' x 3.12' x 2.46 |

2.28 m³ |

|

|

SC-887-M5.5 |

8’ x 8’ x 7’ |

8.29' x 8.29' x 8.60' |

660 W |

2 |

2300 m³ /h (1360 cfm) |

8.2' x 3.12' x 1.8' |

1.31 m³ |

|

|

SC-8107-M5.5 |

8’ x 10’ x 7’ |

8.23' x 10.34' x 8.60' |

740 W |

2 |

2300 m³ /h (1360 cfm) |

10.5' x 3.12' x 1.97' |

1.82 m³ |

|

|

SC-8127-M5.5 |

8’ x 12’ x 7’ |

8.29' x 12.26' x 8.60' |

780 W |

2 |

2300 m³ /h (1360 cfm) |

12.47' x 3.02' x 1.64' |

1.75 m³ |

|

|

SC-8167-M5.5 |

8’ x 16’ x 7’ |

8.29' x 16.29' x 8.60' |

660 W |

2 |

2300 m³ /h (1360 cfm) |

8.53' x 3.12' x2.43' |

1.84 m³ |

|

|

SC-8207-M5.5 |

8’ x 20’ x 7’ |

8.29' x 20.32' x 8.60' |

780 W |

2 |

2300 m³ /h (1360 cfm) |

10.5' x 3.12' x 2.3' |

2.91 m³ |

|

|

SC-10127-M5.5 |

10’ x 12’ x 7’ |

10.32' x 12.26' x 8.60' |

740 W |

2 |

2300 m³ /h (1360 cfm) |

11.02' x 4.27' x 1.8' |

2.4 m³ |

|

|

SC-12127-M5.5 |

12’ x 12’ x 7’ |

12.36' x 12.36' x 8.60' |

820 W |

2 |

2300 m³ /h (1360 cfm) |

13.06' x 3.12' x 2.3' |

2.65 m³ |

|

|

SC-12167-M5.5 |

12’ x 16’ x 7’ |

12.36' x 16.29' x 8.60' |

1240 W |

4 |

4600 m³ /h (2720 cfm) |

12.8' x 3.12' x 2.3' |

2.59 m³ |

|

|

SC-12207-M5.5 |

12’ x 20’ x 7’ |

12.36' x 20.32' x 8.60 |

1440 W |

4 |

4600 m³ /h (2720 cfm) |

13.12' x 2.95' x 2.3' |

2.52 m³ |

|

OPTIONS

-

All stainless steel construction

-

Leveling feet

-

Complete factory test and certification, including airflow, filter integrity, particle counting, light and noise tests

-

Extensions for existing Soft Capsule cleanrooms