Pharmacon™ Downflow Booths (DFB)

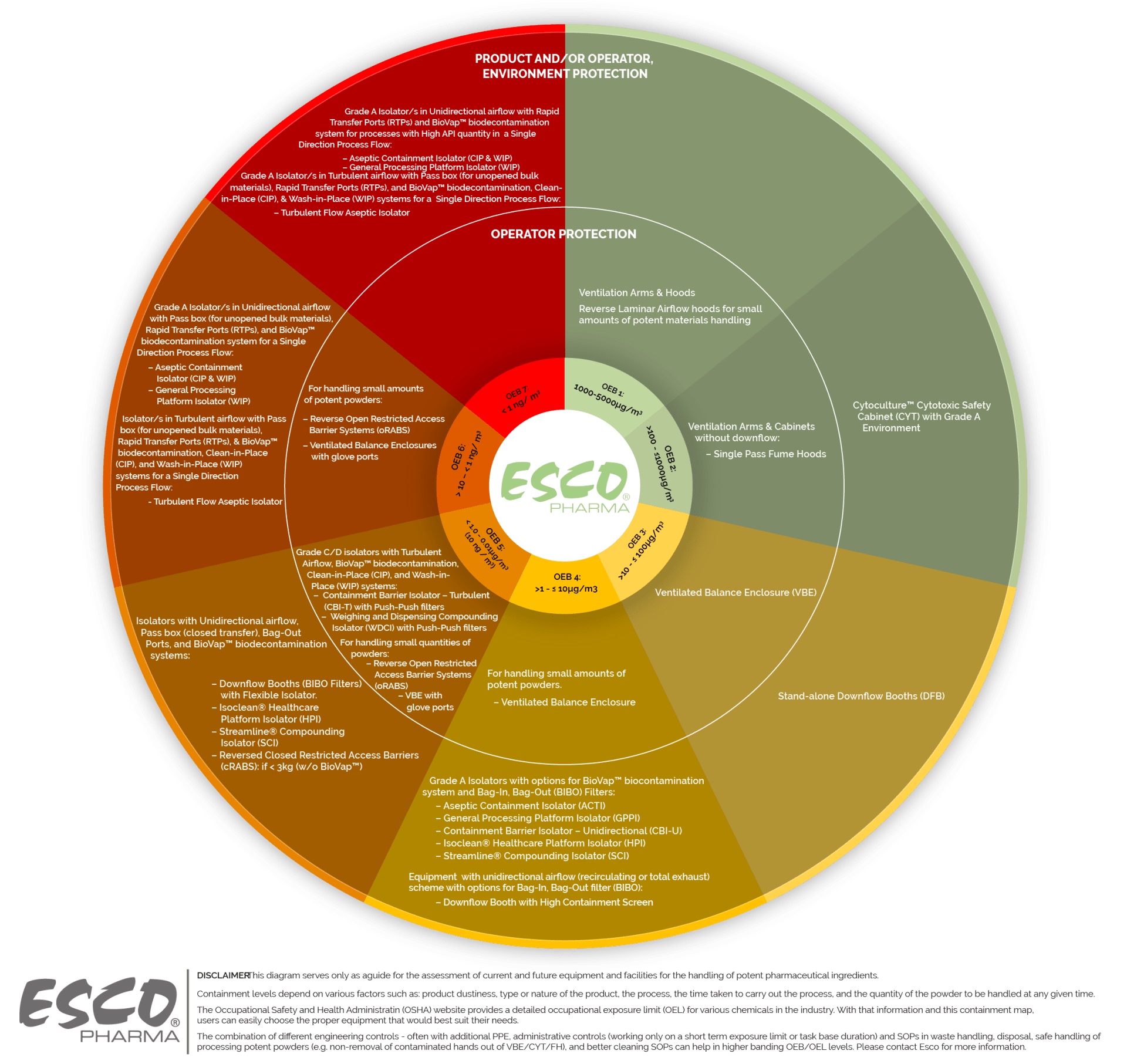

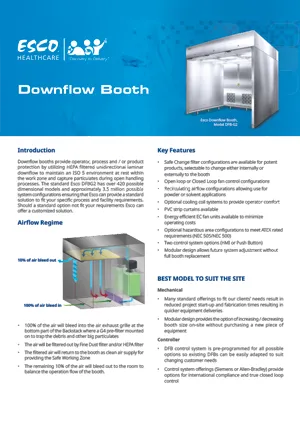

Esco Healthcare Downflow Booth (DFB) is designed in compliance with international cGMP guidelines. DFB provides operator, process and / or product protection during open handling processes such as: weighing / dispensing or charging of powder into intermediate bulk container (IBC), bins or equivalent, and sampling in cGMP warehouses by utilizing HEPA filtered unidirectional laminar downflow to maintain an ISO Class 5 environment at rest within the work zone and capture particulates during open handling processes.

Standard Esco DFB has over 420 possible dimensional models with approximately 3.5 million possible system configurations. As an established manufacturer and supplier of sampling / dispensing booths, Esco Healthcare can guarantee a standard solution to fit your specific process and facility requirements. Should a standard option not fit your requirements, Esco can offer a customized solution.

Pharmacon™ DFB Applications

- Pharmaceutical

- Cosmetics

- Nutraceutical

- Food

- Biological

- Animal

- Robotic

- Electronic

Closed Loop

Closed Loop Fan Control

Standard blowers used by Pharmacon™ DFB are closed loop ECM fans. These are energy-efficient blowers with the ability to automatically adjust fan speed in response to filter loading. Open loop configurations are also available, along with recirculating airflow options suitable for powder or solvent applications.

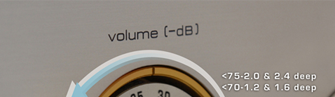

Whisper Quiet

75 dBa is Possible

Noise level of ≤75 dBa can be achieved during factory testing; carried out in free field with clean filters and without sound foam. Energy-efficient EC fan units help minimize operating costs while maintaining quiet operation.

Tool-Less Replacement/Maintenance

Rapid Tool-less Filter Replacement/Maintenance

The sampling booth is equipped with knife-edge gel sealed filters capable for a ‘rapid tool-less replacement’ within the booth. Safe Change filter configurations are available for potent products, with options to change either internally or externally to the booth. Integrated filter challenge ports support compliant filter integrity testing.

ISO Class 5 Air Quality (at rest)

Esco Pharma DFB can achieve ISO Class 5 air quality (at rest conditions) with its wide array of standard filtration options. Up to six different filter configurations are available, utilizing combinations of G4, F8, Carbon, H13, and H14 filters. Client can specify the type based on their application (dust burden level).

Lighting System

Energy Efficient Lighting & Optimized Airflow

Flush mounted energy efficient LED light fixtures in the booth side walls or ceiling ensures minimal glare and sufficient lighting in the work zone. LED lighting design placement ensures improved airflow regime with the minimum distance between the ceiling HEPA filters and diffusers.

Improved Airflow Characteristics

LED lighting design placement ensures improved airflow regime with the minimum distance between the ceiling HEPA filters and diffusers.

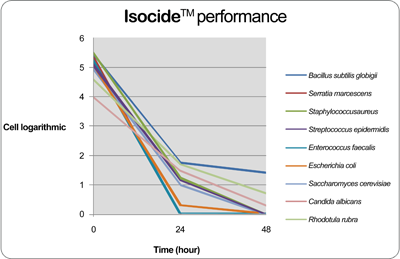

ISOCIDE™ antimicrobial coating

Antimicrobial Powder Coating

For powder coated sampling / weighing booths, Esco Pharma utilizes the Isocide™ anti-microbial powder coating on all panels.

Modular Design & Control Systems

The booth features a cGMP modular design with minimized joints and seams, allowing future system adjustment without full booth replacement. Multiple control system options are available, including HMI, Push Button, or Sentinel Gold Microprocessor interfaces. Optional hazardous area configurations can be provided to meet ATEX rated requirements (NEC 505/NEC 500).

Environmental & Operator Comfort Enhancements

Optional cooling coil systems are available to enhance operator comfort. PVC strip curtains are also available to support environmental separation.

Principle

- Air is delivered into the Operator’s Breathing Zone (OBZ) via the overhead HEPA filters, thus providing a clean and safe environment.

- Potential dust clouds are suppressed and removed via the exhaust filtration system.

- The operator carries out tasks in the high velocity zone at the rear of the Booth so that dangerous dusts will not rise into the breathing zone.

- Product protection is assured by customising the downflow booth’s layout to suit the processes being carried out.

- The Booth provides a stand-alone work place that doesn’t require the connection of external ventilation systems.

|

|

0.3 m Back Stack |

0.6 m Back Stack |

1.0 m Back Stack |

|

|

Series |

Option SC: Safe Change |

|

|

✓ |

|

Option SCNB: Safe Change No-Bag |

|

|

✓ |

|

|

Option ST: Standard |

✓ |

✓ |

|

|

|

Explosive Rating |

Option SA : Safe Area |

✓ |

✓ |

✓ |

|

Option ED: Explosive Dust |

|

✓ |

✓ |

|

|

Option EG: Explosive Gas |

|

✓ |

✓ |

|

|

Dimensional Option |

Internal Height Options (m) |

2.1, 2.5 |

2.1, 2.5 |

2.1, 2.5 |

|

External Width Options (m) |

1.6, 1.8, 2.0, 2.4, 2.6, 2.8,

3.0, 3.2, 3.4, 3.6, 3.8, 4.0, 4.2, 4.4, 4.6, 4.8, 5.0 |

1.6, 1.8, 2.0, 2.4, 2.6, 2.8,

3.0, 3.2, 3.4, 3.6, 3.8, 4.0, 4.2, 4.4, 4.6, 4.8, 5.0 |

1.6, 1.8, 2.0, 2.4, 2.6, 2.8,

3.0, 3.2,3.4, 3.6, 3.8, 4.0, 4.2, 4.4, 4.6, 4.8,5.0 |

|

|

Internal Depth Options (m) |

0.8, 1.2, 1.6 |

0.8, 1.2, 1.6, 2.0, 2.4 |

0.8, 1.2, 1.6, 2.0, 2.4, 2.8 |

|

|

Filter Arrangement Options |

Option A - G4,F8,H13,H14,PLF |

|

|

✓ |

|

Option B - G4,F8,H13,H14 |

|

|

✓ |

|

|

Option C - G4,F8,H13,PLF |

|

|

✓ |

|

|

Option D - G4,F8,H14 |

|

✓ |

✓ |

|

|

Option E - Carbon,H14 |

✓ |

|

✓ |

|

|

Fan / Filter Access |

Option A - Internal to Booth |

✓ |

✓ |

✓ |

|

Option B - External Area |

|

|

✓ |

|

|

Airflow Arrangement |

Option R - Recirculating |

✓ |

✓ |

✓ |

|

Option S - Single Pass with

Downflow Air |

|

|

✓ |

|

|

Bleed Position |

Option T - Top |

|

|

✓ |

|

Option F - Front |

✓ |

✓ |

✓ |

|

|

M.O.C. Options |

Option P: Ceiling Plenum |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

|

Option Q: Side Panels, Rear Wall |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

|

|

Option R: Filter Housings, Fan

Boxes, Spacer (if present) & Transition |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

|

|

Option S: Plinth |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

|

|

Option T: Exhaust Grills |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

|

|

Option U: Exterior Side Panels |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

A: 316SS, B: 304 SS, C: White

P.C. EG Steel |

|

|

PVC Curtains |

Option T - Top |

|

|

✓ |

|

Option F - Front |

✓ |

✓ |

✓ |

|

|

Voltage Supply |

Option A: 230 V, 50 Hz, 1 Ph |

✓ |

|

|

|

Option B: 400 V, 50 Hz, 3 Ph |

|

✓ |

✓ |

|

|

Option C: 208 V, 60 Hz, 3Ph |

|

✓ |

|

|

|

Option D: 480 V, 60 Hz, 3 Ph |

|

✓ |

✓ |

|

|

Option E: 120 V, 60 Hz, 1 Ph |

✓ |

|

|

|

|

MCP Location |

OR: Onboard Right Access |

✓ |

✓ |

✓ |

|

OL: Onboard Left Access |

✓ |

✓ |

✓ |

|

|

OF: Onboard Front Access |

✓ |

|

|

|

|

RM: Remote Mounted |

✓ |

✓ |

✓ |

|

|

Control Type |

Option 1: PLC/PB's/PDI/PDT -

Allen Bradley Components - Closed Loop |

|

✓ |

✓ |

|

Option 2: PLC/PB's/PDI/ PDT -

Siemens Components - Closed Loop |

|

✓ |

✓ |

|

|

Option 3: PLC/HMI/PDT - Allen

Bradley Components - Closed Loop |

|

✓ |

✓ |

|

|

Option 4: PLC/HMI/PDT - Siemens

Components - Closed Loop |

|

✓ |

✓ |

|

|

Option 5: Sentinel Gold/PDI/ PDT

- Open Loop/Closed Loop |

✓ |

✓ |

✓ |

|

|

Cooling Type |

Option CC: Chilled Water |

|

✓ |

✓ |

|

Option DX: Direct Expansion |

|

✓ |

✓ |

|

|

Option GL: Glycol |

|

✓ |

✓ |

|

Notes: * Explosive Rating requires full definition at the time of enquiry

|

Mechanical |

Many standard offerings to fit our client's needs result in reduced

project start-up and fabrication times resulting in quicker equipment

deliveries |

|

Modular design provides the option of increasing / decreasing booth

size on-site without purchasing a new piece of equipment |

|

|

Controls |

DFB control system is pre-programmed for all possible options so

existing DFBs can be easily adapted to suit changing customer needs |

|

Control system offerings (Siemens, AB, Sentinel Controller) provide

options for international compliance and true closed loop control |

|

|

Sales |

Automated DFBG2 sales tool allows for instant quoting and drawing

generation to greatly reduce the time between RFQ and quote submittal |

|

Options |

|||

|

|

High Containment Screen |

|

Material Handling |

|

|

Bench; SST or Granite Tables, W x D, Fixed to Booth or Stand Alone |

|

Vision Panel |

|

|

Computer Monitor Mounting Screen |

|

Ethernet & RS-232 Pass Through Connections |

|

|

Airlock |

|

Bumper Rails |

|

|

Standard woodhead Duplex Outlet |

|

Temperature & RH Local Display |

|

|

Pass Through |

|

Drum Tipper |

|

|

Side Wall Fire Sprinkler Penetration |

|

|

Containment Levels