Streamline® Closed Restricted Access Barrier System (SLC-RABS)

The Streamline® Closed Restricted Access Barrier System (SLC-RABS) provides a safe and clean environment for the preparation of sterile non-hazardous drugs in compliance to the United States Pharmacopeia General Chapter <797>.

Closed Restricted Access Barrier System (cRABS) provides a full unidirectional airflow scheme for an ISO Class 5 environment for aseptic processing. SLC-RABS is designed with a rigid wall enclosure and glove port access for process manipulation; this prevents the risk of cross-contamination. The interior of the enclosure is manually sanitised with process components introduced via pass-through chambers.

As such, cRABS provide superior sterility as compared to open front clean air devices (laminar flow clean benches and Class II biological safety cabinets). These systems are a safe and efficient solution for the production of low-volume pharmaceuticals as well as with practices concerning:

Operator aseptic technique training

Expiration settings

Product quality maintenance (once CSP leaves the pharmacy)

Furthermore, cRABS can reduce operating and renovation costs by taking up less space than a traditional cleanroom facility.

- ULPA filters (as per IEST-RP-CC001.3 and HEPA (H14) filter as per EN 1822) with a typical efficiency of >99.995% at 0.1 to 0.3 microns, providing ISO Class 5 air cleanliness as per ISO 14644-1.

- Sentinel™ Gold Microprocessor controller supervises all functions and monitors airflow and pressures in real-time.

- For negatively pressured RABS, the work zone and pass-through chambers are under negative pressure to the room to maintain operator protection in the event of a breach in the system.

- Positively pressured configurations are under positive pressure to the room to ensure product protection.

- Robust dual-wall construction. The work zone is surrounded by negative pressure plenums at the sides and back. Unique Esco Dynamic Chamber™ plenum surrounds filter seals with negative pressure.

- Ergonomically angled front and oval gloveports improve reach and comfort.

- Safe-change cuff rings permit glove changing with zero risk of contaminating the work zone and/or pharmacy environment.

- Easy to clean one-piece work zone liner.

- Esco antimicrobial coating on all painted surfaces to minimize contamination.

- Sharps disposal system and hydraulic height adjustable stand are available as options.

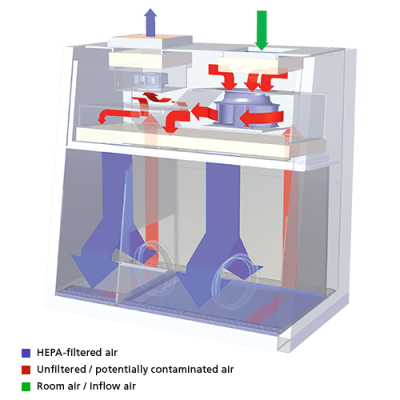

Recirculating Airflow

- Ambient air is pulled through the inlet pre-filter and main filter located on top of the isolator.

- The downflow filter creates a laminar air flow providing ISO Class 5 air cleanliness (ISO 14644-1) to the main chamber and pass-through, with a down flow velocity of 0.30 m/s +/- 20%.

- Air from the work zone and pass-through is quickly purged out by the exhaust fan to keep the area clean. The fan pulls approximately 70% of the purged air back to the plenum, passes through the HEPA downflow filter again, and is recirculated back to the work zone and pass-through.

- Approximately 30% of the purged air is exhausted through the filter to prevent heat build-up inside the isolator.

- Exhausted air is replenished by ambient air coming from the top inlet prefilter that has 80% efficiency.

|

Streamline® Closed - Restricted Access Barrier System |

|||||||||||

|

SLC-RABS-4N3-S |

|||||||||||

|

Unit |

Model |

Nominal Width |

Pressure Scheme |

Electrical Code |

Sharps Provision |

||||||

|

Streamline® Closed - Restricted Access Barrier System |

SLC-RABS |

4 |

4 ft (1.2 m) |

N |

Negative |

1 |

220-240 V, AC, 50 Hz, 1Ø |

0 |

No |

||

|

2 |

110-120 V, AC, 50 Hz, 1Ø |

||||||||||

|

6 |

6 ft (1.8 m ) |

P |

Positive |

S |

Yes |

||||||

|

3 |

220-240 V, AC, 60 Hz, 1Ø |

||||||||||

|

SLC-RABS-4N-_- |

SLC-RABS-4P-_- |

SLC-RABS-6N-_- |

SLC-RABS-6P-_- |

||

|

Nominal Size |

1.2 meters (4’) |

1.8 meters (6’) |

|||

|

External Dimensions |

Witout Base Stand |

1340 x 820 x 1320 mm (52.8” x 32.3” x 51.9”) |

1950 x 820 x 1320 mm (76.8” x 32.3” x 51.9”) |

||

|

With Base Stand (Min) |

1522 x 820 x 1995 mm (59.9” x 32.3” x 78.5”) |

2132 x 820 x 1995 mm (83.9” x 32.3” x 78.5”) |

|||

|

With Base Stand (Max) |

1522 x 820 x 2250 (59.9” x 32.3” x 88.6”) |

2132 x 820 x 2250 mm (83.9” x 32.3” x 88.6”) |

|||

|

Main Chamber Work Zone (W x D x H) |

840 x 610 x 670 mm (33.1” x 24.0” x 26.4”) |

1450 x 610 x 670 mm (57.1” x 24.0” x 26.4”) |

|||

|

Pass Through (W x D x H) |

355 x 610 x 670 mm (13.9” x 24.0” x 26.4”) |

355 x 610 x 670 mm (13.9” x 24.0” x 26.4”) |

|||

|

Work Zone and Interchange Chamber Performance |

ISO Class 5 (Class 1, Federal Standard 209E) |

||||

|

Inlet Filter Type |

80% efficienct pre-filters |

||||

|

Downflow and Exhaust Filter Type |

HEPA filter with integral metal guards and filter frame gaskets; fully compliant with EN 1822 (H14) and IEST-RP-CC001.3 requirements (each cabinet has individual downflow, exhaust filters and inlet filters). |

||||

|

Typical Filter Efficiency |

>99.995% for particle size between 0.1 to 0.3 micron |

||||

|

Fluorescent Lamp Intensity |

> 950 Lux (>88 foot candles) |

||||

|

RABS Construction |

Main Body |

1.2 mm (0.05”) 18 gauge electro-galvanized steel with white oven-baked epoxy-polyester antimicrobial powder-coated finish |

|||

|

Work Tray |

1.5 mm (0.06”) 16 gauge stainless steel, type 304, with 4B finish |

||||

|

Side Walls |

1.2 mm (0.05”) 18 gauge stainless steel, type 304, with 4B finish |

||||

|

Electrical |

220-240V, AC, 50Hz, 1Ø |

SLC-RABS-4N1-_ |

SLC-RABS-4P1-_ |

SLC-RABS-6N1-_ |

SLC-RABS-6P1-_ |

|

Cabinet Full Load Amps (FLA) |

2.1 A |

2 A |

2.5 A |

2 A |

|

|

Optional Outlets FLA |

5 A |

5 A |

5 A |

5 A |

|

|

Cabinet Nominal Power |

295 W |

301 W |

440 W |

345 W |

|

|

Cabinet BTU |

1007 |

1027 |

1501 |

1177 |

|

|

110-120V, AC, 60Hz, 1Ø |

SLC-RABS-4N2-_ |

SLC-RABS-4P2-_ |

SLC-RABS-6N2-_ |

SLC-RABS-6P2-_ |

|

|

Cabinet Full Load Amps (FLA) |

6 A |

4 A |

8.2 A |

7 A |

|

|

Optional Outlets FLA |

5 A |

5 A |

5 A |

5 A |

|

|

Cabinet Nominal Power |

410 W |

264 W |

600 W |

456 W |

|

|

Cabinet BTU |

1399 |

901 |

2047 |

1556 |

|

|

220-240V, AC, 60Hz, 1Ø |

SLC-RABS-4N3-_ |

SLC-RABS-4P3-_ |

SLC-RABS-6N3-_ |

SLC-RABS-6P3-_ |

|

|

Cabinet Full Load Amps (FLA) |

2.1 A |

2 A |

2.5 A |

2 A |

|

|

Optional Outlets FLA |

5 A |

5 A |

5 A |

5 A |

|

| Cabinet Nominal Power | 295 W | 301 W | 440 W | 345 W | |

|

Cabinet BTU |

1007 |

1027 |

1501 |

1177 |

|

|

Shipping Dimensions, Maximum (W x D x H) |

1590 x 990 x 2210 mm (62.6” x 39.0” x 87.0”) |

2150 x 950 x 2210 (84.6” x 37.4” x 87.0”) |

|||

|

Shipping Volume, Maximum* |

3.48 m³ (122.9 cu.ft) |

4.51 m³ (159.3 cu.ft) |

|||

|

* SLC-RABS only; excludes optional stand. ** Cabinet and GFCI outlet operate on a single power cord. |

|||||

Standard Accessories

Airlock pass-through

Vertical pass-through door

Horizontal tray for easy material transfer

Electrical Outlets and Utility Fittings

Electrical outlet, ground fault, North America

Electrical outlet, Euro/Worldwide

Support Stands

Fixed height, available 711 mm (28") or 864 mm (34") - With levelling feet, ± 38.1 mm (1.5") (SAL-_ _ 0) - With casters (SPC-_ _0)

Telescoping height stand for levelling feet (STL-_ _0), nominal range 660 mm to 960 mm (26"to 37.8")

Telescoping height stand for casters (STC-_ _0), nominal range 660 mm to 880 mm (26" to 34.6") - Adjustable in 25.4 mm (1") increments

Infinitely adjustable hydraulic stand with casters elevates to accommodate a sitting or a standing user’s work surface height (SHM-_A0)

Options

Electrical outlets

-

UV lamp

*Note: Clearly indicate in PO as UV lamp for SLC-RABS is factory-installed. Sharps disposal system

Alarm package

Exhaust carbon filter

Thimble exhaust collar

Perforated shelf to increase work zone space

*Note: This option is available for customized units.

- Solenoid valve

- IV Bar with Hooks

- Manual volumetric damper

- Service fixture

- European Style

- American Style

*Note: This option is available for customized units.