Weighing and Dispensing Containment Isolator (WDCI)

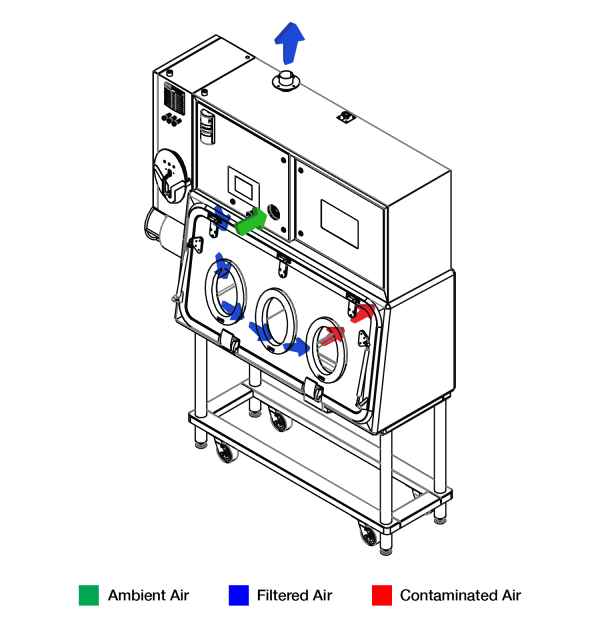

The Esco Weighing and Dispensing Containment Isolators (WDCI) are advanced containment systems providing controlled negative pressure environments to maximize personnel protection during weighing and dispensing of potent compounds.

Esco WDCIs’ provide standard configurable designs that are able to adapt to various weighing and dispensing quantities and accuracies.

-

The isolator is constructed from a fully welded single-piece 4.0 mm thick SS316L stainless steel internal chamber with rounded coved corners and a low surface finish for easy cleaning.

-

It is pressure tested per ISO 10648-2 Class 2 containment requirements, achieving a leak rate of less than 0.25% volume loss per hour.

-

Inflatable antibacterial gaskets, compliant with 21 CFR 177.2600 and FDA-approved, provide both proactive and reactive sealing to maintain safety and integrity.

-

An integrated automated pressure decay testing system allows fast, accurate, and repeatable chamber integrity checks without disrupting operations.

-

The isolator features clean, polished interior and exterior surfaces to meet GMP requirements and reduce the risk of cross-contamination.

-

Push-push safe-change filters enable efficient in-process filter replacement while maintaining full containment protection.

-

Lighting is positioned externally to the isolator chamber for ease of servicing, enhanced illumination, and improved process chamber cleanliness.

-

Engineered for high-potency applications, delivering assured operator protection down to 1 ng/m³

| General Specification | 2-glove | 3-glove | 4-glove | 5-glove | Pass Chamber | |

| Nominal Size Process Chamber | 1200 mm | 1600 mm | 2000 mm | 2400 mm | 680 mm | |

| External Dimension (WxDxH) - with 1 pass chambers | 1990 x 924 x 2275 mm | 2390 x 924 x 2275 mm | 2790 x 924 x 2275 mm | 3190 x 924 x 2275 mm | N/A | |

| Chamber Internal Dimension (WxDxH) | 1200 x 633 x 842 mm | 1600 x 633 x 842 mm | 2000 x 633 x 842 mm | 2400 x 633 x 842 mm | 682 x 532 x 842 mm | |

| Chamber Pressure | Negative Pressure | |||||

| Airflow Type | Turbulent Flow | |||||

| Filter Type and Efficiency | Inlet | Push-push 99.995% @ 0.3µm MPPS | Cartridge 99.98% @ 0.3µm MPPS | |||

| Exhaust | Push-push 99.995% @ 0.3µm MPPS | Cartridge 99.98% @ 0.3µm MPPS | ||||

| Exhaust Volume (cmh) | During normal run | 20cmh @300Pa | 30cmh @300Pa | 40cmh @300Pa | 50cmh @300Pa | 15cmh @250Pa |

| During breach | 100cmh @900Pa | 100cmh @900Pa | 100cmh @900Pa | 100cmh @900Pa | 100cmh @900Pa | |

| Lighting Level | ≥ 500 Lux | N/A | ||||

| Sound Level | ≤ 75 dBa | |||||

| Isolator Material and Finish | Internal Chamber | SS316L, 4.0mm, Ra: ≤ 0.40 µm | ||||

| External Chamber | SS304, 4.0mm, Ra: ≤ 0.60 µm | |||||

| Service Housing External | SS304, 2.0mm, Ra: ≤ 0.60 µm | |||||

| Door Seals | Silicone, Inflatable Seals, 21 CFR 177.2600 Compliant | |||||

| Support Frame | SS304, 2.0mm, Ra: ≤ 1.20 µm | |||||

| Electrical Requirements | 110-120V, AC, 50Hz/60Hz, 1Ø | |||||

| 220-240V, AC, 50Hz/60Hz, 1Ø | ||||||

| 480V, AC, 50Hz/60Hz, 3Ø | ||||||

| Compressed Air Requirements | 6 Bar g Minimum, 12 Bar g maximum, @ ≥50L/min flow capacity | |||||

| Exhaust Duct Requirements (by Client) | 3" (DN80) | |||||

| Chamber Cleanliness | ISO Class 7 | |||||

| Process Chamber Air Change per Hour | > 30 ACH | |||||

| Water supply for Spray Gun | 5 m3/hr (83L/min) @ 4.0 bar gauge or more | |||||

| Glove Port | Oval, 200 x 300 mm | |||||

| Glove | Single-piece, glove-sleeve system, with Chlorosulfonated Polyethylene material | |||||

| Control System | HMI 12" as Standard with PLC (Industrial PC Upgrade with SCADA Integration is available as an Optional) | |||||

- Pass chamber left and right

- Automated or manual drain valve

- Sloped working zone

- Wet-in-place with spray gun using purified water and compressed dry air supply

- Wet-in-place with spray ball using purified water with compressed dry air supply

- Split butterfly valve (4”)

- Rapid transfer port alpha: Ø105, Ø190, Ø270, Ø350

- Rapid transfer port beta container, polyethylene or stainless steel: Ø105, Ø190, Ø270, Ø350

- Rapid transfer port beta continuous liner

- Bag-out port: Ø170, Ø200, Ø300

- Integrated glove leak tester

- CCTV provision

- Raise and lower adjustable height support stand

- Electrical outlets (IP-54, IP-65 rated)

- Nitrogen purge system to lower chamber relative humidity

- Integrated oxygen sensors Amber or yellow light for light sensitive materials