Market Demand for HPAPI Rises; Containment Technologies to Meet it Head-on

Recent Pharmaceutical Market

The continuous expansion of the biopharmaceutical market, particularly, the global demand in the field of medical oncology, calls for an increase in the development and conventional drug manufacturing of high potency active pharmaceutical ingredients (HPAPIs). Within the next 5 years, the value for cancer medication is estimated to reach 100 billion USD.

The major problem with this is that human intervention is present at almost every stage of the manufacturing process, thus, increasing the risk for personnel exposure. This could lead to various adverse health effects to all personnel involved; that is why, ensuring the safety of the manufacturing personnel is of high importance. However, addressing this issue should not impede productivity.

The primary solution is to look into the market for containment technologies which have since diversified into isolators, restricted access barrier systems (RABS), and even the split butterfly valves (SBVs). All of these systems are currently in use by numerous pharmaceutical firms to safeguard the final products, the personnel, and the environment in all stages of manufacturing.

ISPE SMEPAC Guide

The market projection on HPAPIs has led pharmaceutical companies to increase investment in high potency facilities and innovative containment equipment to protect the health of their workers. However, with the complex nature of potent drugs, implementation and installation of containment technologies are not as easy as it seems; and containment verification of these systems is very critical. There needs to be a proper procedure in place, and validation protocols of the equipment to warrant its particulate containment performance.

The market projection on HPAPIs has led pharmaceutical companies to increase investment in high potency facilities and innovative containment equipment to protect the health of their workers. However, with the complex nature of potent drugs, implementation and installation of containment technologies are not as easy as it seems; and containment verification of these systems is very critical. There needs to be a proper procedure in place, and validation protocols of the equipment to warrant its particulate containment performance.

During the late 1990s, the qualification of containment technologies were based on the measurement of worker exposure. This method was later on formalised by the International Society for Pharmaceutical Engineering (ISPE) and became known as the Standardised Measurement of Equipment Particulate Airborne Concentration (SMEPAC). Since then, all containment systems have been validated based on this guideline.

The purpose of the SMEPAC test is to evaluate the containment performance without risking operator exposure to the potent active pharmaceutical ingredient (API) whose analytical method has been or is yet to be analysed. Also, it is used to obtain baseline data for choosing the most effective containment technology found in the market then later on, check its performance prior to actual production process.

This testing method involves the use of a surrogate or substitute material (lactose, paracetamol, mannitol, or naproxen) to represent an API during the simulation of a workplace operation. This allows the test to effectively evaluate containment performance of an equipment without exposing the testers to the actual potent API or hazardous material.

The results of containment performance testing with a surrogate material provides insight into the containment level that can be achieved by the unit. This however, does not directly compare with materials of different physical properties (e.g. different flow characteristics, moisture content or particle size). Additionally, the results with surrogate materials do not guarantee compliance with an occupational exposure level (OEL) established for a specific API. This test also does not evaluate exposure to gases or vapors.

Furthermore, validation testing is essential to guarantee that even with operator intervention, containment capability of the device is not obstructed.

In order to properly evaluate the equipment, sampling locations should be determined based on the critical points of the system wherein the possibility of personnel exposure is high.

After the installation and validation of the equipment, the institution should then focus on the preventive maintenance as frequent monitoring will help maintain the capability and reliability of the containment solution.

Containment Practices

Containment technologies are rapidly evolving over the past decade in order to address the increasing demands of handling potent compounds and to remove risks of occupational exposure.

It is a common misconception that containment performance is directly linked to the levels of visible particulate residue after separation to the containment device, however, this issue has been rebutted by actual results of the performance tests. There are newly developed extraction methods which has led to the recovery of potential airborne particulates which offers a solution to achieve performance repeatability of these equipment.

As a preventive measure, other ways to increase operator protection is to utilize good laboratory practices of hazardous drug handling like: double gloving technique, proper decontamination and cleaning procedures, and appropriate waste disposal.

In Conclusion

With the imminent rise of demand for HPAPIs, pharmaceutical industries continue to use innovative containment strategies, and as important it is to get these technologies, it is also critical that their containment capability and repeatability is validated using highly developed test procedures. This is the only way to ensure the overall protection towards the final product, the manufacturing personnel, and the environment.

Esco Pharma Turn-key Solutions

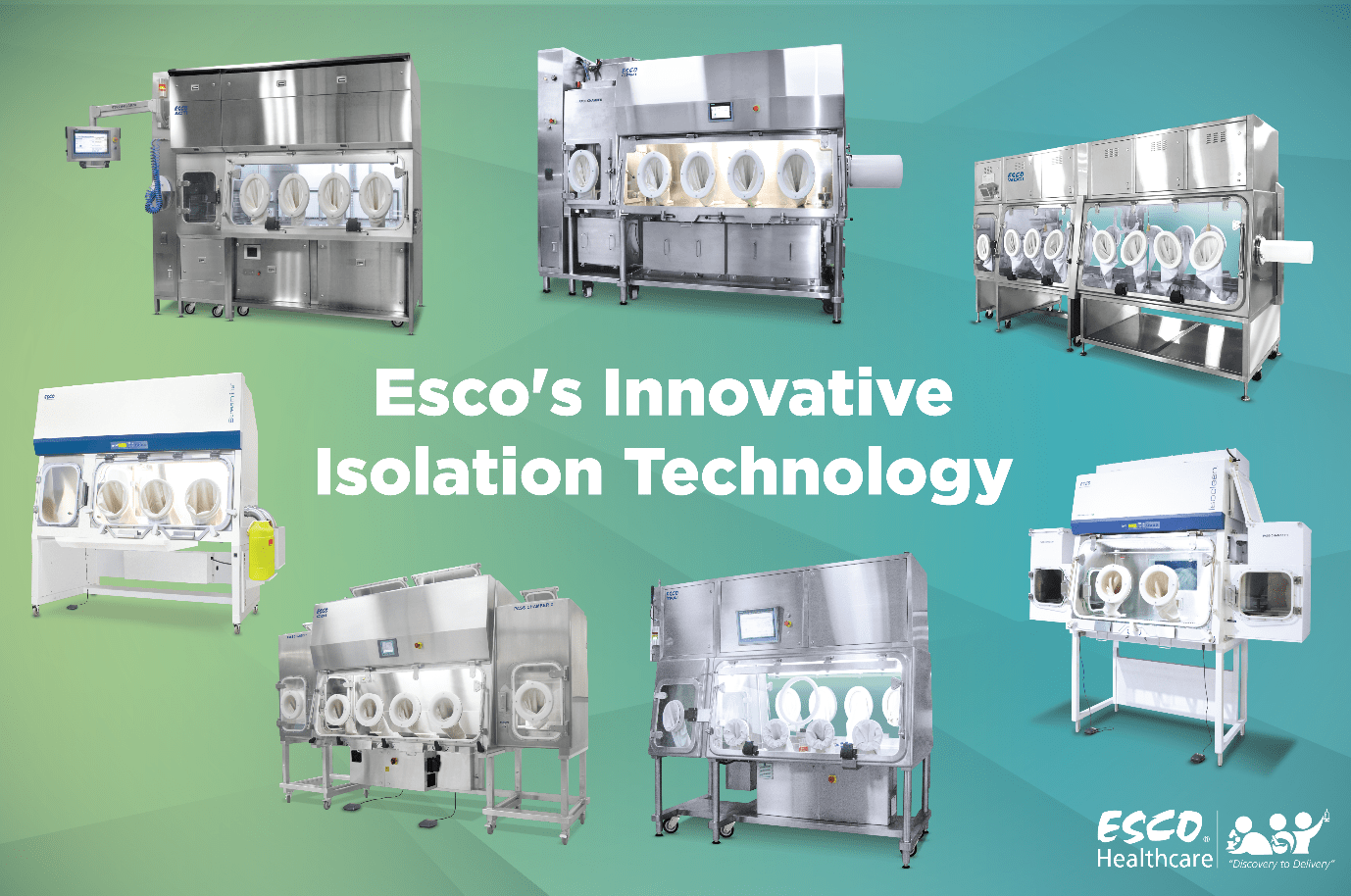

The containment experts of Esco Pharma are continuously developing ways to innovate their systems and be the leaders in the field. Check out the wide range of isolation technologies that Esco offers!

References:

- 1. Avraam, Michael. (2019). Understanding ISPE SMEPAC Guidelines and Considerations in HPAPI Containment Testing. Retrieved on 14-July-2019. Retrieved from: https://www.pharmaceuticalonline.com/doc/understanding-ispe-smepac-guidelines-and-considerations-in-hpapi-containment-testing-0001

- 2. ISPE. (2012). Assessing the Particulate Containment Performance of Pharmaceutical Equipment, 2nd ed. Tampa, Florida 33609 USA.