RABS vs Isolators: Understanding the differences

During the last 2 decades, aseptic processing has advanced with the use of isolators and Restricted Access Barrier Systems (RABS) as a means of detaching the operator from “critical areas” thereby reducing potentials risks in products. These systems have been slowly replacing traditional cleanroom.

But what exactly are the differences between these two systems?

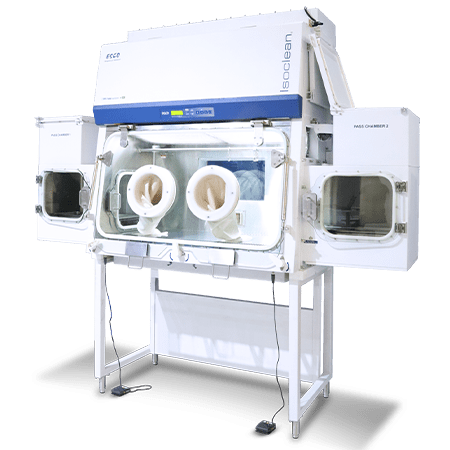

Restricted Access Barrier System (RABS)

- Includes Compounding Aseptic Isolator (CAI) or Compounding Aseptic Containment Isolator (CACI)

- Provide an ISO Class 5 environment for preparing Compounded Sterile Preparations (CSPs)

- All transport ports must be closed during compounding

- Located within at least ISO Class 7 area to prepare Category 2 CSPs, or within a segregated compounding area to prepare Category 1 CSPs

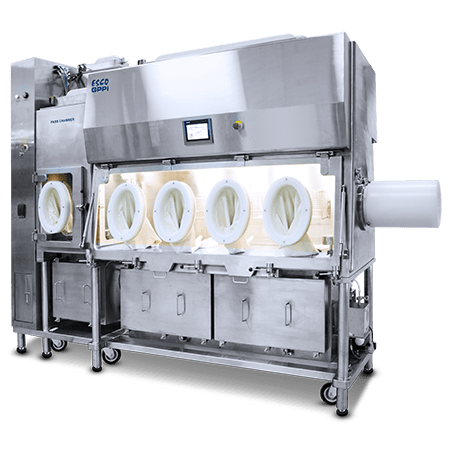

Isolator

- Provides isolation from the surrounding area and maintains ISO Class 5 air quality

- High-integrity transfer ports

- Decontaminated using an automated system

- Maintains constant overpressure of at least 0.05-inch water column

- Can be located in an ISO Class 8 area when preparing Category 2 CSPs

|

Criteria |

RABS | ISOLATOR |

| Decontamination | Manually disinfected |

Quantifiable and high reproducible method by an automated system |

| Assurance of Separation | No complete physical separation |

Quantifiable hourly leak rate (closed) and continuously controlled differential pressure |

| Surrounding Environment |

Passive: ISO 5 Active: ISO 7 |

Quantifiable leakage tightness (ISO 10648-2) |

| Capital Costs |

Higher than conventional cleanroom (CCR); reduced with renovation and retrofit application |

HIgh equipment costs |

| Operating Costs |

Higher than CCR |

Cost saving in energy consumption (HVAC) and clothing |

| Toxic Containment |

Low Capability |

Good reliability |

Source: Innovation in Aseptic Manufacturing RABS versus Isolators by Francesco Longanesi (Feb 2008)

Esco offers ISOLATORS apt for your compounding needs!

ESCO RABS

ESCO ISOLATORS