Discovery to Delivery

› News ›Application and Technology News

Pharmaceutical industries need to gain a high degree of assurance that their manufacturing processes are consistently producing marketable drug products with the necessary attributes of identity, strength, quality, purity, and potency.

Novel drugs do not just appear overnight, rather, they are borne from the ceaseless sacrifice of dedicated researchers. The story starts with exhaustively studying a promising compound and ends with a safe and properly documented final drug product in the market.

Recent studies on antibiotic occupational exposure has shown evidences of high AMR levels and various adverse health effects among production line workers without proper equipment to isolate them from the process.

GMP, or Good Manufacturing Practice is one of the most important guidelines followed in the field of pharmacy. It tackles all aspects of production - from the raw materials, the facility, to the equipment.

Kilo labs, also called pilot scale manufacturing, are able to mimic plant conditions to ensure that the desired form or polymorph of the active pharmaceutical ingredient is obtained.

Pharmaceutical manufacturers developed the Oral Film Technology (OFT), also known as Orodispersible films (ODFs), fast dissolving films, or fast disintegrating films. This type of pharmacokinetic mechanism allows it to avoid first-pass metabolism, thus, providing a fast onset of action with enhanced bioavailability.

The determination of personnel and environmental potential exposure is usually required for the safe handling of high potency active pharmaceutical ingredients (HPAPIs). A selective process in selecting the most appropriate strategies is also a must for the assurance of containment.

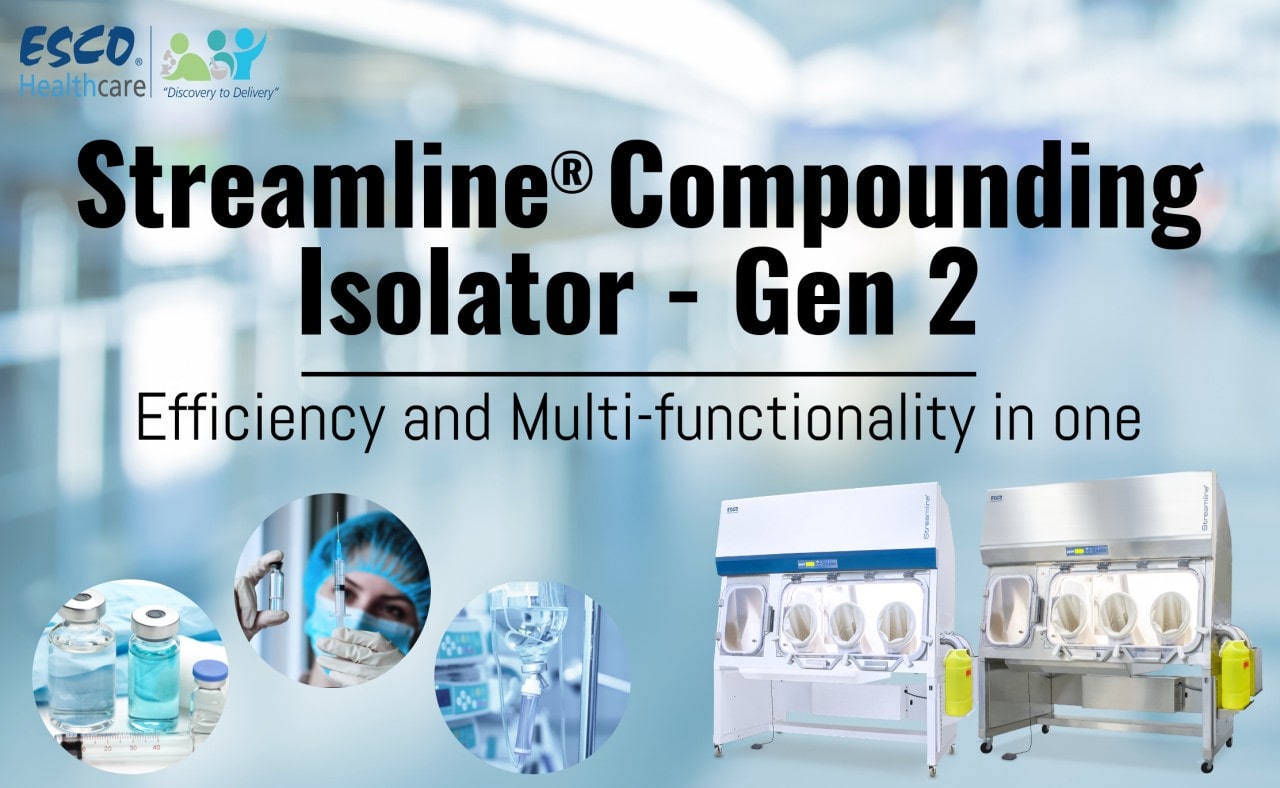

Esco welcomes 2019 with an innovative and internationally compliant equipment to add to its line of isolation technology: the Streamline® Compounding Isolator - Gen 2 (SCI-G2).

Sign up to our newsletter and receive the latest news and updates about our products!