Discovery to Delivery

› News ›Application and Technology News

Many modern medicines are highly potent, with only tiny doses required to achieve a therapeutic effect. But a nanomolar medicine poses extra hazards during manufacturing, whether the product is a biologic or a small molecule.

Ensuring food safety starts with production, at the farm level. In this regard, misuse of agro-chemicals, including pesticides, growth hormones and veterinary drugs may have harmful effects on human health.

Pharmaceutical industry now utilize Nanotechnology as a platform for new technology development. It is the science that deals with the processes that occur at molecular level and of nanolength scale size.

For the past few decades, pharmaceutical companies are investing on modernized ways and methods to find a viable way to get insulin into the bodies of people with diabetes without needles. Naturally the idea of an insulin inhaler, similar to an asthma inhaler, was an appealing prospect.

In the large scale production of medicines quality, is not achieved by accident. It is result of a carefully constructed quality assurance system. This system must ensure that each medicinal product conforms to its intended use.

A defect is an undesirable characteristic of a product. It is defined as a failure to conform to specifications or a unit of a product which contains one or more defects is called a defective.

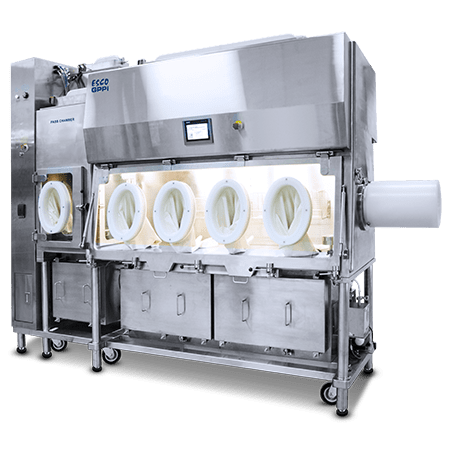

During the last 2 decades, aseptic processing has advanced with the use of isolators and Restricted Access Barrier Systems (RABS) as a means of detaching the operator from "critical areas" thereby reducing potentials risks in products.

Protecting yourself from highly hazardous materials doesn't have to make you look out of this world.

Sign up to our newsletter and receive the latest news and updates about our products!